2023-01-07

Magnetic Scale Read Head | Differences Between Encoder Resolution, Accuracy and Repeatability

Magnetic Scale Read Head | Magnetic grating encoder products have many parameters such as resolution, accuracy, and repeatability; they may seem similar but differ in meaning. Today we explore the differences among these three parameters.

1. Resolution

Resolution is the smallest motion increment the magnetic scale can detect. The measurement method varies by encoder type.

For linear magnetic encoders, resolution is a length step typically measured in µm, calculated as pole pitch divided by subdivision factor. In printing, it is often expressed as DPI (dots per inch).

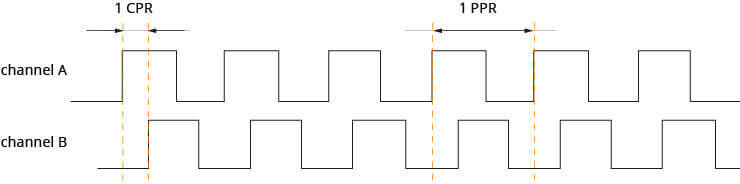

For rotary magnetic encoders, resolution can be expressed in arcseconds, arcminutes, degrees, percent of revolution, or radians. For absolute rotary encoders, resolution is the number of measurement steps per full 360° rotation, e.g., a 13-bit absolute encoder provides 2^13 = 8192 steps per revolution. Incremental rotary encoders define resolution by PPR (pulses per revolution) and CPR (counts per revolution). PPR counts from one rising edge to the next; CPR counts rising and falling edges on two channels. Multiplying PPR by 4 yields CPR electronically.

Illustration: one CPR and one PPR

Resolutions are categorized roughly as:

· For linear magnetic encoders

o High resolution: <100 nm

o Medium resolution: 200 nm - 10 µm

o Low resolution: >50 µm

· For rotary magnetic encoders

o High resolution: >18 bits

o Medium resolution: 13 - 17 bits

o Low resolution: <12 bits

Choose an encoder with resolution equal to or better than the application requirement.

2. Accuracy

Accuracy measures how close the output is to the true value — the difference between the actual position and the encoder's reported position, or the maximum measurement error.

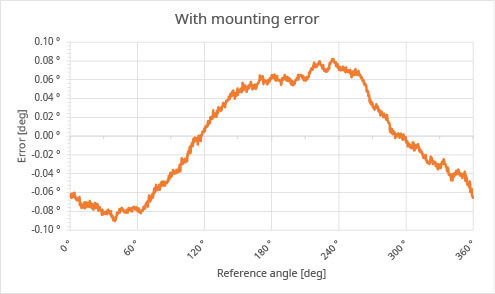

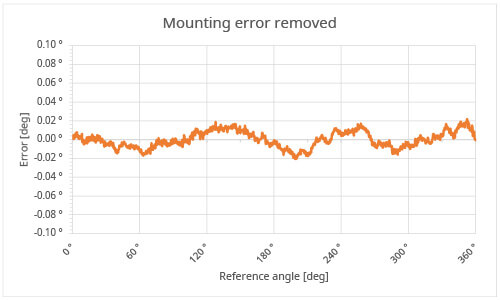

Magnetic encoder accuracy combines errors from the scale and the read head. For rotary encoders accuracy is often expressed in arcseconds or degrees; for linear encoders it is commonly in µm per unit length (µm/m). Note that high resolution does not automatically imply high accuracy.

With installation error

Remove installation error

3. Repeatability

Repeatability is the maximum difference among multiple measurements taken at the same actual position.

Unidirectional repeatability is the difference among repeated measurements taken under the same direction and conditions. Electronic noise, temperature changes, and component aging can cause reported positions to vary over time. Repeatability is often included in accuracy specifications; as a rule of thumb, repeatability is typically 5-10 times better than accuracy for a given encoder.

Bidirectional repeatability is the difference among measurements taken in opposite directions under the same conditions.

A system may have high repeatability but still lack sufficient accuracy. The distinction between accuracy and repeatability is illustrated above. For many applications, repeatability is the most important encoder parameter, such as in robotic repeatable motion control.

Difference between accuracy and repeatability

Above is an overview of the differences among Magnetic Scale Read Head and Magnetic Grating Encoder resolution, accuracy, and repeatability. Atonm manufactures magnetic scales designed for linear displacement detection, making displacement measurement simple and precise. Atonm's magnetic scale read head provides an open and reliable linear measurement system that is oil-, water-, dust-, and shock-resistant, tolerant to grease, and suitable for high-humidity and extreme temperature environments. It can replace glass scales and displacement sensors and substantially reduce cost. Atonm Magnetic Scale Read Head is suitable for woodworking and stone-processing machines, linear motors, semiconductors, LCD and panel equipment, high-precision automation lines, glass inspection tables, glass edging machines, press brakes, hydraulic presses, laser cutting, CNC machines, and boring mills.

You May Be Interested

-

Atonm MDSC-9000T Dual-Channel, Single-Sensor Metal Double-Sheet Detector

2025-12-05

-

Non-Contact “One-to-Four” Double-Sheet Detector 1600S: A New Cost-Reduction and Efficiency Solution for Stamping Lines

2025-11-20

-

Mold damage, production delays? Atonm MDSC-8200T metal double-sheet detector protects automotive stamping lines

2025-10-30

-

Provincial Auto Industry Research Tour | Atonm Engages with the Automotive Supply Chain, Empowering Smart Manufacturing through Sensors

2025-10-11