Become a trusted sensing solution partner in the automotive stamping field

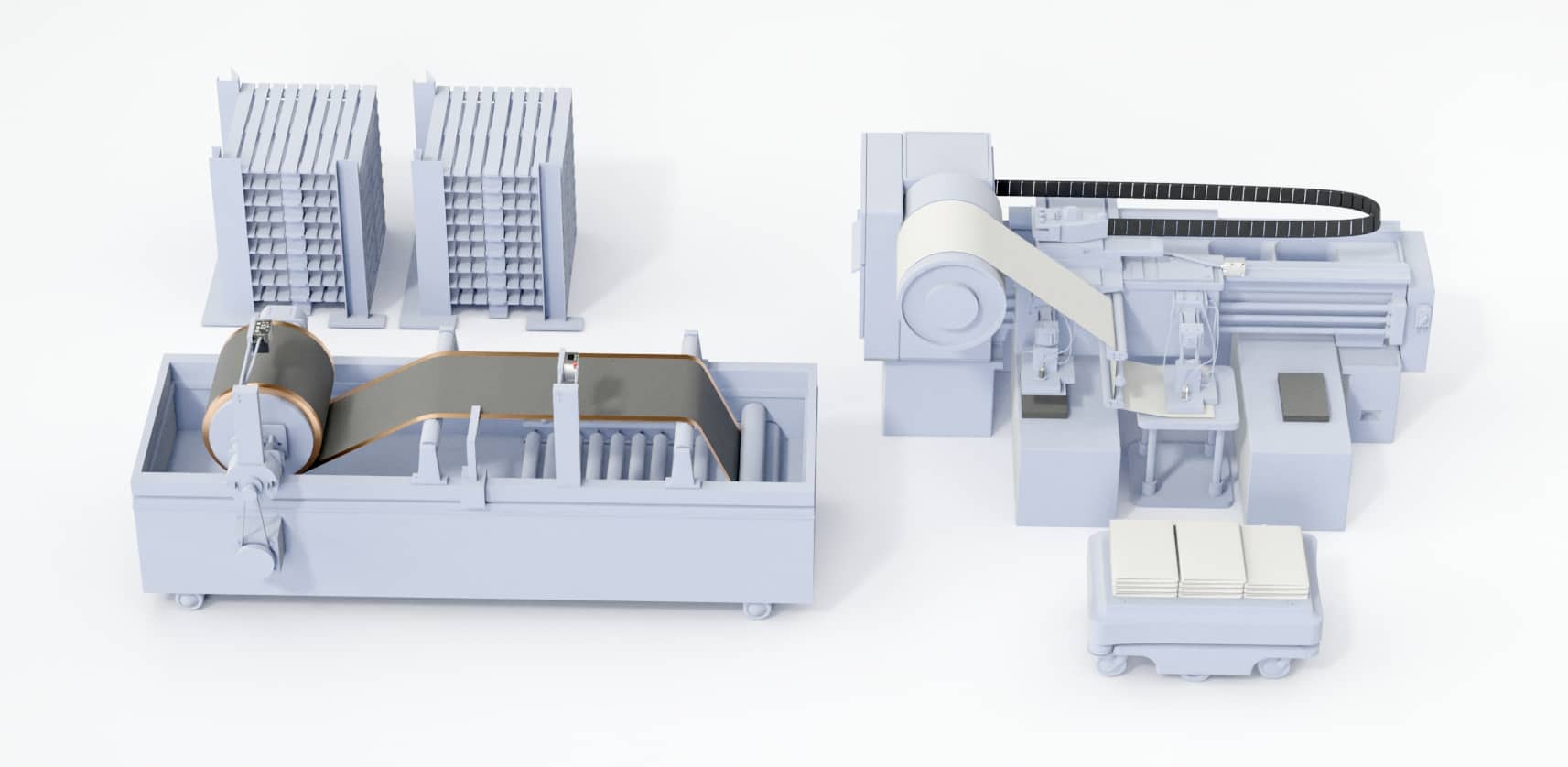

In automotive stamping production, double-sheet misfeeding is a high-risk factor causing die damage and unplanned downtime. Atonm focuses on metal double-sheet detection applications, with targeted designs for detection stability, response speed and system compatibility under high-speed feeding and continuous stamping conditions, delivering reliable long-term solutions for stamping lines.

-

High-speed feeding stable detection

For high-speed feeding and short cycle conditions, Atonm double-sheet detectors have fast response and stable output capabilities, accurately identifying single and double-sheet states under continuous operation, reducing misjudgments that affect stamping cycle and equipment stability.

-

Multi-condition material adaptation

Faced with variations in sheet material, thickness and surface conditions, Atonm enables adaptation to the stamping requirements of multiple vehicle models and processes through flexible parameter configuration and multi-formula storage capabilities, reducing engineering burdens caused by frequent debugging and improving on-site application stability.

-

Seamless integration with industrial control systems

Atonm Double-Sheet Detection Solution supports mainstream industrial communication protocols, enabling direct integration with feeding, stamping and safety control systems. It achieves efficient linkage between detection signals and equipment actions, helping engineers complete system integration and on-site deployment quickly.

Solution for Automotive Industry

Providing stable and reliable double-sheet detection and feeding safety comprehensive solutions for automotive stamping production lines

Single-sensor Double-sheet Detector

Image Sensor

Double-sensor Double-sheet Detection

-

Adopts a dual-channel design, supporting dual-station and multi-point simultaneous detection; compatible with magnetically permeable/non-magnetically permeable material detection; equipped with a built-in thickness measurement function to prevent material errors from the source; has 999 sets of built-in recipes for efficient and convenient multi-mode production changeover; supports mainstream communication protocols such as 485/Profinet/EtherCat to achieve intelligent system control.

Back to Scenario Overview

Based on the principles of electromagnetic induction and eddy current, the main controller can connect two sensors simultaneously to complete efficient and stable sheet overlapping detection tasks.It has a built-in storage function for 200 sets of sheet parameters, eliminating the trouble of repeated teaching.With an integrated design for both magnetic and non-magnetic materials, it is compatible with all sheet types.It supports both terminal and bus control solutions to achieve intelligent system control.

Back to Scenario Overview

Provide stable and reliable double sheet detection and thickness monitoring solutions for high-tempo production lines: 1000 sets of recipe capacity meet diverse production needs; ≤160ms ultra-fast response adapts to 20SPM production lines in automotive stamping/welding; dual probes support independent thickness setting, with real-time thickness measurement of 0.2-4.0mm ; compatible with original 8200S for direct replacement (compatible with original installation dimensions, no structural modification required); for enterprises' production line transformation needs, provide zero-risk code modification services to ensure seamless integration of equipment into production lines, helping enterprises achieve low-cost and high-efficiency production line transformation.

Back to Scenario Overview

The controller can connect two sensors simultaneously, with a built-in storage for 200 sets of sheet material recipes. It is capable of detecting magnetic conductive metal plates with a thickness of 0.2-4mm, and supports communication methods such as Profinet, 485 and terminal control.

Back to Scenario Overview

It can connect two sensors simultaneously and has a built-in storage for 200 sets of sheet material recipes. It is capable of detecting non-magnetic metal plates with a thickness of 0.2-4mm, and supports communication methods such as Profinet, 485, and terminal control.

Back to Scenario Overview

Provides a stable and reliable double-sheet detection and thickness monitoring solution for high-speed production lines: supports up to 200 recipe groups to meet diverse production requirements; ≤95 ms ultra-fast response for automotive stamping and welding lines operating at 20 SPM; enables thickness presetting with real-time thickness measurement from 0.2 to 4.0 mm (accuracy 3%).

Back to Scenario Overview

Tailored to the characteristics of large sheet materials in the automotive manufacturing and auto parts production industries as well as the requirement for single-side sensor installation, it realizes double-sheet feeding detection with a single-side probe.

Back to Scenario Overview

Tailored for large sheet materials in the automotive manufacturing and auto parts production industries, it meets the requirement of single-side sensor installation and achieves double-sheet feeding detection with a single-sided probe.

Back to Scenario Overview

-

integrates high-performance image sensing and intelligent AI processing, boasting a maximum of 2.3 megapixels and three adjustable resolutions. Equipped with rich interfaces and an exposure control module, it is suitable for multiple scenarios such as automated production and quality inspection. It supports functional customization and features industrial-grade reliability.

Back to Scenario Overview

-

Non-contact "one-to-four" multi-probe design enables detection of stacked materials of various materials such as iron, steel, aluminum, copper, and stainless steel; high-speed response adapts to high-speed stamping production lines; upgraded with 999 sets of recipes for quick production changeover and compatible with mainstream communications including IO/Profinet/EtherCat, providing a cost-reducing, efficiency-enhancing, and localized double-material detection upgrade solution for production lines.

Back to Scenario Overview

MDSC-1500S is a through-type double-sheet detector capable of detecting both magnetic and non-magnetic materials. It adopts a new generation of sensor technology with excellent anti-interference performance, ensuring stable detection in various complex environments. The device supports IO and PN communication modes, enabling remote teaching and learning of sheet materials, which greatly improves the flexibility and convenience of operation. With a built-in storage function for 200 sets of sheet parameters, it easily adapts to production lines with frequent material changes.

Back to Scenario Overview

-

Single-sensor Double-sheet Detector

-

Adopts a dual-channel design, supporting dual-station and multi-point simultaneous detection; compatible with magnetically permeable/non-magnetically permeable material detection; equipped with a built-in thickness measurement function to prevent material errors from the source; has 999 sets of built-in recipes for efficient and convenient multi-mode production changeover; supports mainstream communication protocols such as 485/Profinet/EtherCat to achieve intelligent system control.

-

Based on the principles of electromagnetic induction and eddy current, the main controller can connect two sensors simultaneously to complete efficient and stable sheet overlapping detection tasks.It has a built-in storage function for 200 sets of sheet parameters, eliminating the trouble of repeated teaching.With an integrated design for both magnetic and non-magnetic materials, it is compatible with all sheet types.It supports both terminal and bus control solutions to achieve intelligent system control.

-

Provide stable and reliable double sheet detection and thickness monitoring solutions for high-tempo production lines: 1000 sets of recipe capacity meet diverse production needs; ≤160ms ultra-fast response adapts to 20SPM production lines in automotive stamping/welding; dual probes support independent thickness setting, with real-time thickness measurement of 0.2-4.0mm ; compatible with original 8200S for direct replacement (compatible with original installation dimensions, no structural modification required); for enterprises' production line transformation needs, provide zero-risk code modification services to ensure seamless integration of equipment into production lines, helping enterprises achieve low-cost and high-efficiency production line transformation.

-

The controller can connect two sensors simultaneously, with a built-in storage for 200 sets of sheet material recipes. It is capable of detecting magnetic conductive metal plates with a thickness of 0.2-4mm, and supports communication methods such as Profinet, 485 and terminal control.

-

It can connect two sensors simultaneously and has a built-in storage for 200 sets of sheet material recipes. It is capable of detecting non-magnetic metal plates with a thickness of 0.2-4mm, and supports communication methods such as Profinet, 485, and terminal control.

-

Provides a stable and reliable double-sheet detection and thickness monitoring solution for high-speed production lines: supports up to 200 recipe groups to meet diverse production requirements; ≤95 ms ultra-fast response for automotive stamping and welding lines operating at 20 SPM; enables thickness presetting with real-time thickness measurement from 0.2 to 4.0 mm (accuracy 3%).

-

Tailored to the characteristics of large sheet materials in the automotive manufacturing and auto parts production industries as well as the requirement for single-side sensor installation, it realizes double-sheet feeding detection with a single-side probe.

-

Tailored for large sheet materials in the automotive manufacturing and auto parts production industries, it meets the requirement of single-side sensor installation and achieves double-sheet feeding detection with a single-sided probe.

-

-

Double-sensor Double-sheet Detection

-

Non-contact "one-to-four" multi-probe design enables detection of stacked materials of various materials such as iron, steel, aluminum, copper, and stainless steel; high-speed response adapts to high-speed stamping production lines; upgraded with 999 sets of recipes for quick production changeover and compatible with mainstream communications including IO/Profinet/EtherCat, providing a cost-reducing, efficiency-enhancing, and localized double-material detection upgrade solution for production lines.

-

MDSC-1500S is a through-type double-sheet detector capable of detecting both magnetic and non-magnetic materials. It adopts a new generation of sensor technology with excellent anti-interference performance, ensuring stable detection in various complex environments. The device supports IO and PN communication modes, enabling remote teaching and learning of sheet materials, which greatly improves the flexibility and convenience of operation. With a built-in storage function for 200 sets of sheet parameters, it easily adapts to production lines with frequent material changes.

-

-

Image Sensor

-

integrates high-performance image sensing and intelligent AI processing, boasting a maximum of 2.3 megapixels and three adjustable resolutions. Equipped with rich interfaces and an exposure control module, it is suitable for multiple scenarios such as automated production and quality inspection. It supports functional customization and features industrial-grade reliability.

-

Products and solutions have been continuously applied and recognized by many automotive OEMs

-

2,000+ Clients

Long-term application verification by industry clients

-

999Memorys

Multi-condition flexible adaptation capabilities

-

30+Items

A Strong Portfolio of Core Technology Patent Rights

Want to Learn More?

Our professional team looks forward to partnering with you to explore more opportunities and possibilities