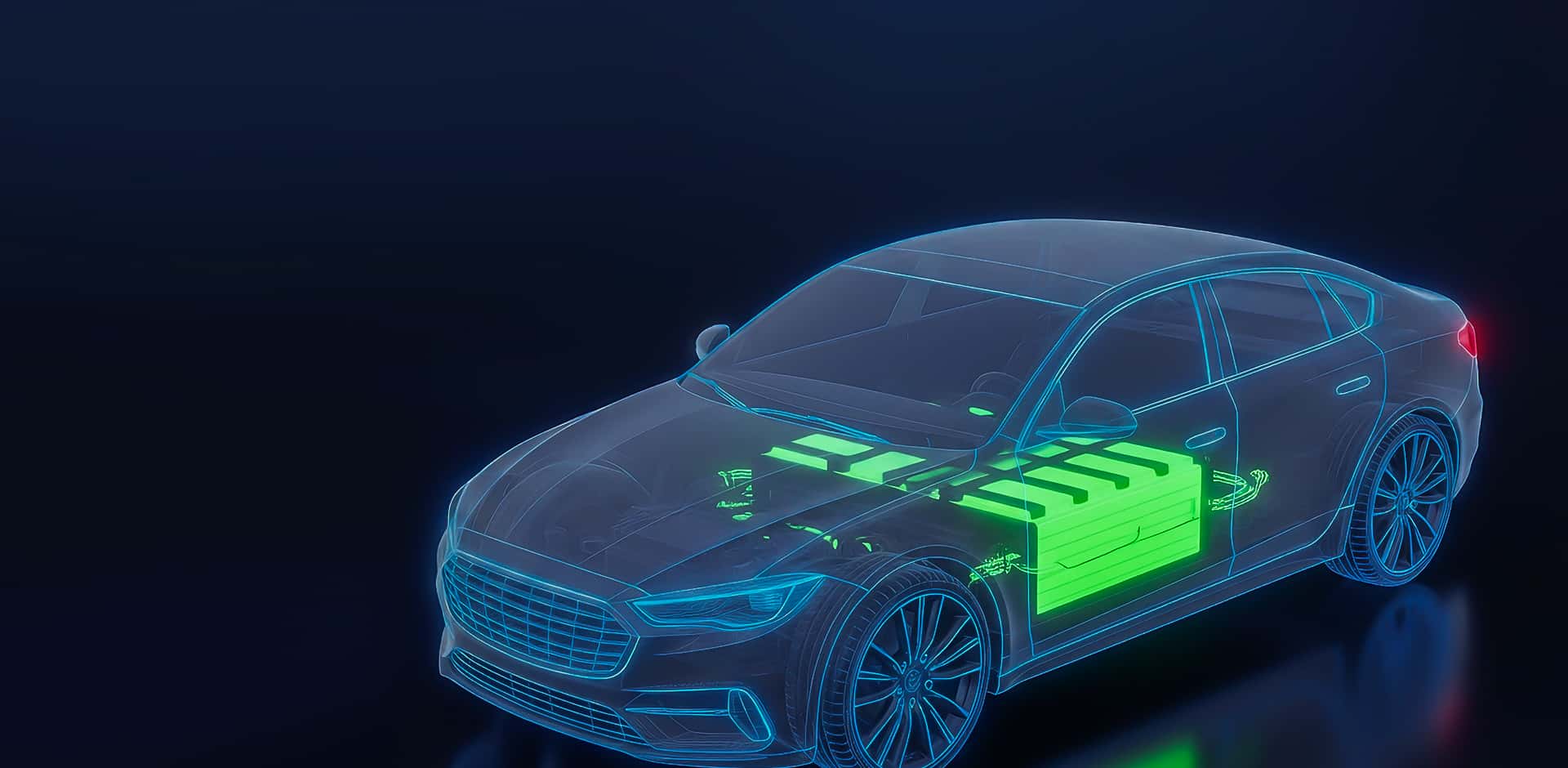

With precise perception, support the upgrade of lithium battery manufacturing

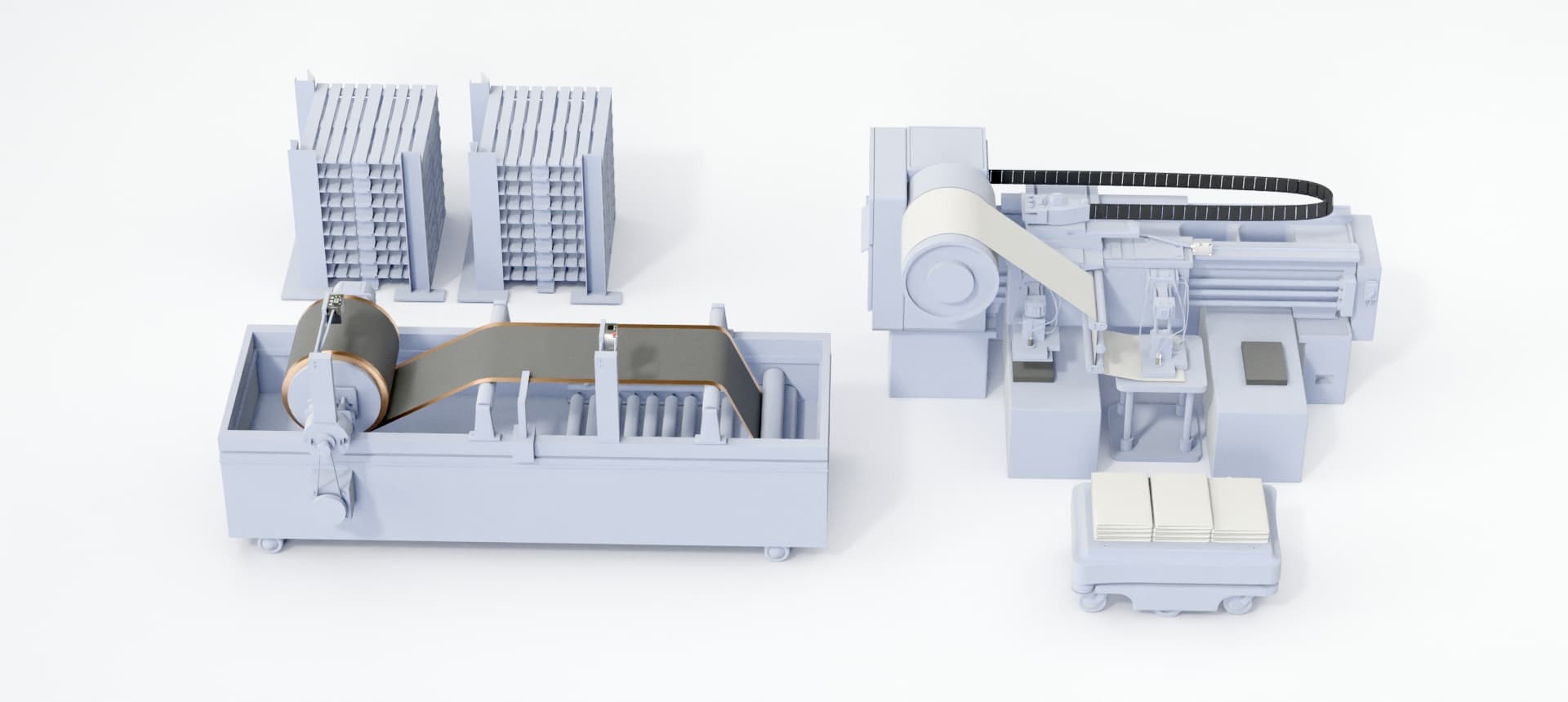

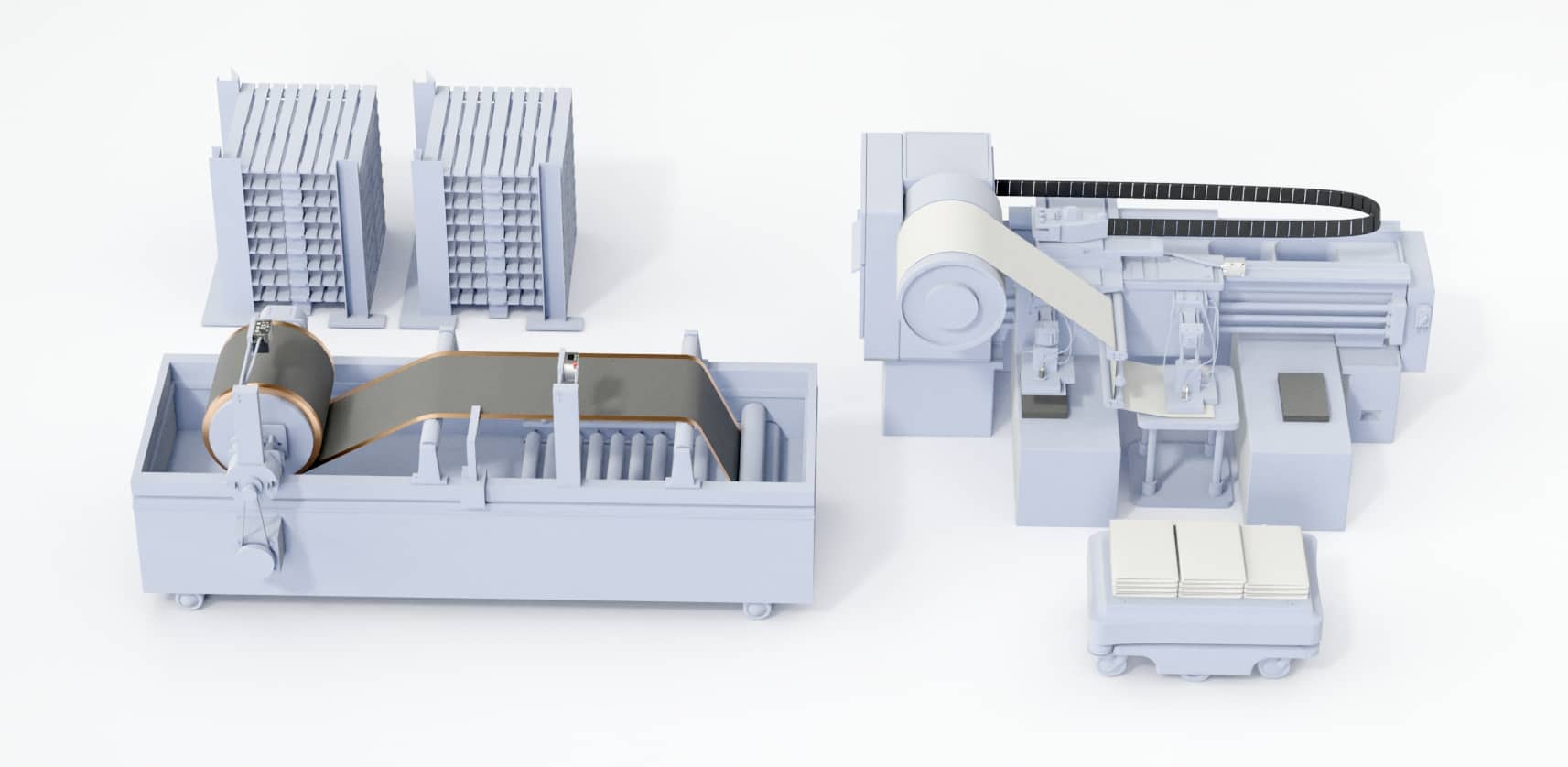

In lithium battery production, stacking misfeeds are high-risk factors leading to equipment failures, unplanned downtime, and performance degradation. Atonm has developed multi-condition, multi-formula, and multi-parameter configuration detection solutions for lithium battery stacking scenarios, providing long-term operational detection solutions for lithium battery production. Focusing on the stringent requirements for precision, consistency, and stability in lithium battery manufacturing, Atonm centers on multi-sensor collaboration, continuously refining key technologies such as laser displacement, magnetic scales, color mark recognition, and double-sheet detection, building detection solutions for core processes like winding and stacking, helping customers improve process controllability and product consistency.

-

Adhere to Core Technology R&D

Atonm consistently focuses on independent research and development around key industrial detection links, continuously investing from sensing principles, signal processing to application implementation, constantly improving product stability under high precision, high speed, and complex conditions, providing a reliable perception foundation for lithium battery manufacturing.

-

Deeply Adapt to Process Scenarios

Closely aligned with the actual needs of key processes such as winding and stacking, Atonm deeply integrates sensor capabilities with equipment processes, providing directly implementable detection solutions for core parameters such as position, thickness, alignment, color marks, and stacking status, helping customers reduce debugging difficulty and accelerate production line commissioning.

-

Multi-sensor Collaborative Solutions

Through the collaboration of multiple sensors such as laser displacement, magnetic scales, color mark recognition, and double-sheet detection, Atonm's detection solutions achieve comprehensive perception of key parameters in lithium battery manufacturing, enhancing process controllability, ensuring product consistency, and helping customers improve overall manufacturing levels.

Li-battery Solutions

Providing collaborative detection solutions for multiple types of sensing products across different processes and application scenarios

Back to Scenario Overview

Double-sheet Detection Solution

Magnetic Scale Displacement Solution

Winding Material Margin Detection Solution

Color Mark Positioning Solution

-

Double-sheet Detection Solution

-

Magnetic Scale Displacement Solution

-

Winding Material Margin Detection Solution

-

Color Mark Positioning Solution

Metal Double-sheet Detector

-

Designed for thin materials in the lithium battery industry; it is equipped with a customized high-sensitivity compact probe sensor, which can be installed and used even on equipment with a compact internal structure, meeting the requirements of high-cycle production.

Back to Scenario Overview

-

This compact single-probe metal sheet overlap detector is especially suitable for installation in confined spaces. It can effectively detect non-magnetic conductive metal sheets, is equipped with 485 communication function, and its design balances convenience and high efficiency.

Back to Scenario Overview

-

Lithium Battery Industry-Specific Double Sheet Detector - Designed for the industry's material characteristics of light weight, small size and thin thickness, it is equipped with customized M8 and M12 small probes to ensure high reliability.

Back to Scenario Overview

Magnetic Scale

-

An open and reliable linear measurement system. It is oil-resistant, waterproof, dustproof, shockproof, oil-pollution resistant, high-humidity resistant, and temperature-resistant (both high and low), making it suitable for various harsh working environments. It can replace products such as linear scales and displacement sensors, significantly reducing costs.

Back to Scenario Overview

-

It adopts high-flexibility and wear-resistant shielded cables and anti-interference hardware & software circuit design, featuring strong anti-interference performance. It meets the requirements of various high-precision displacement measurement scenarios and can withstand complex working environments such as oil pollution, liquids, dust, and vibration. With a compact and exquisite appearance, the product facilitates installation in small spaces.

Back to Scenario Overview

Laser Sensor

-

Digital CMOS laser sensors feature small size, low photoelectric consumption, and high precision; they accurately detect the relative displacement of objects to be measured, and are often used for measuring physical quantities such as length, distance, vibration, speed, and position.

Back to Scenario Overview

-

Digital CMOS laser sensors feature small size, low photoelectric consumption and high precision; they can accurately detect the relative displacement of objects to be measured and are often used for measuring physical quantities such as length, distance, vibration, speed and position.

Back to Scenario Overview

-

Digital CMOS laser sensors feature small size, low photoelectric consumption and high precision; they can accurately detect the relative displacement of objects to be measured and are often used for measuring physical quantities such as length, distance, vibration, speed and position.

Back to Scenario Overview

-

Digital CMOS laser sensors feature small size, low photoelectric consumption and high precision; they can accurately detect the relative displacement of objects to be measured and are often used for measuring physical quantities such as length, distance, vibration, speed and position.

Back to Scenario Overview

-

Digital CMOS laser sensors are characterized by their compact size, low photoelectric power consumption and high precision; they can accurately detect the relative displacement of measured objects and are often used for measuring physical quantities such as length, distance, vibration, speed and orientation.

Back to Scenario Overview

Color Mark Sensor

-

White LED + custom light-receiving component, which can detect based on the appearance (color) of the target object, thus accurately capturing subtle color differences. In addition, since detection is performed based on appearance (color), it is less susceptible to the impact of tilt or distance changes.

Back to Scenario Overview

-

It automatically mixes and generates the required light source for stable color detection. It features intelligent and digital sensitivity adjustment, high-definition dual digital display, and easy operation for quick mastery. The 8-channel design enables simultaneous recognition of 1 color with a 200 μs high-speed response time. Multiple sensor heads are available for selection, resulting in a wide range of applications.

Back to Scenario Overview

-

It supports an RGB three-color light source with triple 16-bit calculation, capable of detecting nearly 3,000 colors and accurately identifying even slight color differences. Adopting an 8-channel output design, it can recognize 4 colors simultaneously. Paired with a variety of color-specific probes, it meets the detection requirements of different sizes and distances.

Back to Scenario Overview

-

Integrated design with compact size; Two-point setup with both color and color mark modes for excellent performance; Adjustable detection hysteresis to eliminate the impact of measured object vibration; The unique dual-mode system features simultaneous color and light intensity detection, ensuring more stable and reliable testing.

Back to Scenario Overview

-

Atonm CE Series is a high-speed intelligent digital color sensor, available in standard and high-performance models. It features dual modes of CoL color detection and Brn color mark detection, supporting output action switching, multiple types of delay functions, and multiple circuit protections. It is suitable for high-speed and high-precision color identification and detection in industrial automation scenarios.

Back to Scenario Overview

-

Double-sheet Detection Solution

-

Designed for thin materials in the lithium battery industry; it is equipped with a customized high-sensitivity compact probe sensor, which can be installed and used even on equipment with a compact internal structure, meeting the requirements of high-cycle production.

-

This compact single-probe metal sheet overlap detector is especially suitable for installation in confined spaces. It can effectively detect non-magnetic conductive metal sheets, is equipped with 485 communication function, and its design balances convenience and high efficiency.

-

Lithium Battery Industry-Specific Double Sheet Detector - Designed for the industry's material characteristics of light weight, small size and thin thickness, it is equipped with customized M8 and M12 small probes to ensure high reliability.

-

-

Magnetic Scale Displacement Solution

-

An open and reliable linear measurement system. It is oil-resistant, waterproof, dustproof, shockproof, oil-pollution resistant, high-humidity resistant, and temperature-resistant (both high and low), making it suitable for various harsh working environments. It can replace products such as linear scales and displacement sensors, significantly reducing costs.

-

It adopts high-flexibility and wear-resistant shielded cables and anti-interference hardware & software circuit design, featuring strong anti-interference performance. It meets the requirements of various high-precision displacement measurement scenarios and can withstand complex working environments such as oil pollution, liquids, dust, and vibration. With a compact and exquisite appearance, the product facilitates installation in small spaces.

-

-

Winding Material Margin Detection Solution

-

Digital CMOS laser sensors feature small size, low photoelectric consumption, and high precision; they accurately detect the relative displacement of objects to be measured, and are often used for measuring physical quantities such as length, distance, vibration, speed, and position.

-

Digital CMOS laser sensors feature small size, low photoelectric consumption and high precision; they can accurately detect the relative displacement of objects to be measured and are often used for measuring physical quantities such as length, distance, vibration, speed and position.

-

Digital CMOS laser sensors feature small size, low photoelectric consumption and high precision; they can accurately detect the relative displacement of objects to be measured and are often used for measuring physical quantities such as length, distance, vibration, speed and position.

-

Digital CMOS laser sensors feature small size, low photoelectric consumption and high precision; they can accurately detect the relative displacement of objects to be measured and are often used for measuring physical quantities such as length, distance, vibration, speed and position.

-

Digital CMOS laser sensors are characterized by their compact size, low photoelectric power consumption and high precision; they can accurately detect the relative displacement of measured objects and are often used for measuring physical quantities such as length, distance, vibration, speed and orientation.

-

-

Color Mark Positioning Solution

-

White LED + custom light-receiving component, which can detect based on the appearance (color) of the target object, thus accurately capturing subtle color differences. In addition, since detection is performed based on appearance (color), it is less susceptible to the impact of tilt or distance changes.

-

It automatically mixes and generates the required light source for stable color detection. It features intelligent and digital sensitivity adjustment, high-definition dual digital display, and easy operation for quick mastery. The 8-channel design enables simultaneous recognition of 1 color with a 200 μs high-speed response time. Multiple sensor heads are available for selection, resulting in a wide range of applications.

-

It supports an RGB three-color light source with triple 16-bit calculation, capable of detecting nearly 3,000 colors and accurately identifying even slight color differences. Adopting an 8-channel output design, it can recognize 4 colors simultaneously. Paired with a variety of color-specific probes, it meets the detection requirements of different sizes and distances.

-

Integrated design with compact size; Two-point setup with both color and color mark modes for excellent performance; Adjustable detection hysteresis to eliminate the impact of measured object vibration; The unique dual-mode system features simultaneous color and light intensity detection, ensuring more stable and reliable testing.

-

Atonm CE Series is a high-speed intelligent digital color sensor, available in standard and high-performance models. It features dual modes of CoL color detection and Brn color mark detection, supporting output action switching, multiple types of delay functions, and multiple circuit protections. It is suitable for high-speed and high-precision color identification and detection in industrial automation scenarios.

-

Want to Learn More?

Our professional team looks forward to partnering with you to explore more opportunities and possibilities