metal double sheet detector MDSC-8200T

- Provide stable and reliable double sheet detection and thickness monitoring solutions for high-tempo production lines: 1000 sets of recipe capacity meet diverse production needs; ≤160ms ultra-fast response adapts to 20SPM production lines in automotive stamping/welding; dual probes support independent thickness setting, with real-time thickness measurement of 0.2-4.0mm ; compatible with original 8200S for direct replacement (compatible with original installation dimensions, no structural modification required); for enterprises' production line transformation needs, provide zero-risk code modification services to ensure seamless integration of equipment into production lines, helping enterprises achieve low-cost and high-efficiency production line transformation.

-

Detection Thickness

Magnetic Materials

0.2-4.0mm

Built-in Sheet Material Storage Recipe

End Effector Quick-Change Adaptation

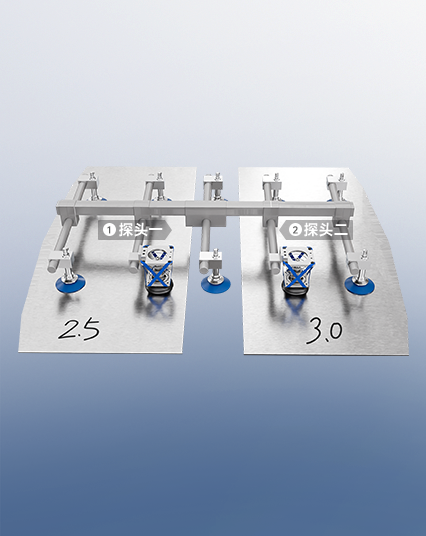

The two probes can detect different thicknesses

Built-in Sheet Material Storage Recipe

999 Groups of Recipes, Enabling Efficient Product Changeover

End Effector Quick-Change Adaptation

No re-learning required after replacing the end effector

Supports Communication

Compatible with mainstream communication protocols such as 485/Profinet/EtherCat

The two probes can detect different thicknesses

Suitable for dual-mode stamping/welding production lines, reducing false detections

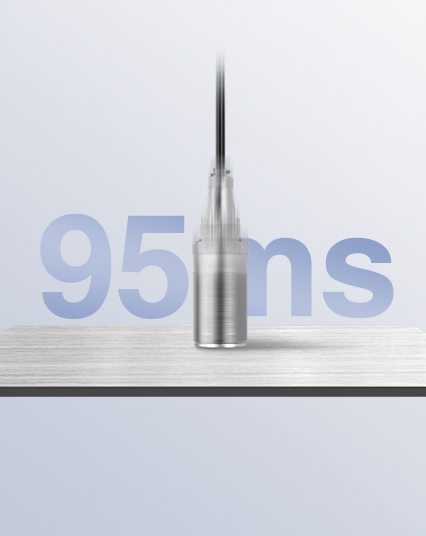

Fast Response Speed

Dual-probe measurement ≤ 160ms, single-probe measurement ≤ 95ms

Note: Products are continuously being innovated and their performance is continually enhanced. The technical specifications provided are for reference only.

Magnetic Materials0.2-4.0mm

Magnetic Materials0.2-4.0mm