2023-01-31

How to Prevent Multiple-Piece Pickups When Feeding Metal Thin Sheets | Overlap Problems?

In automated production a robot gripper may pick up two or more metal thin sheets at once, causing overlap problems that reduce part quality, increase costs and can damage tooling.

How to avoid multiple pickups of metal thin sheets?

Atonm Metal Double-Sheet Detection Controller is developed to address overlapping feeding of metal sheets. The double-sheet detector intelligently recognizes single or multiple sheets and quickly signals downstream equipment to take corrective actions.

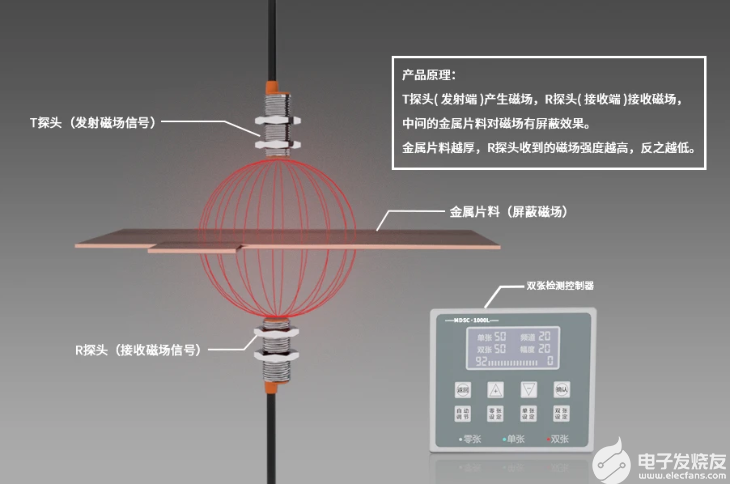

Working principle

The Metal Double-Sheet Detector uses electromagnetic induction based on Oersted principles. T is the transmitter and R is the receiver. As material passes between T and R the magnetic field pattern changes with shielding area and thickness; R sends a differing signal strength to the controller so it can determine single, double or multiple sheets in the sensing zone.

Atonm offers different series tailored to industry material characteristics. The Atonm Metal Double-Sheet Detector 1000L is designed for very light, small and thin metal pieces and uses custom M8/M12 small probes to ensure high reliability. It is suitable for stacking machines, tab welding, PCB depaneling and loading equipment.

Atonm Metal Double-Sheet Detector 1000L

If you face overlap issues in automated feeding, contact Atonm for solutions. Tel: 133-4281-4291 (WeChat same number).

You May Be Interested

-

Atonm MDSC-9000T Dual-Channel, Single-Sensor Metal Double-Sheet Detector

2025-12-05

-

Non-Contact “One-to-Four” Double-Sheet Detector 1600S: A New Cost-Reduction and Efficiency Solution for Stamping Lines

2025-11-20

-

Mold damage, production delays? Atonm MDSC-8200T metal double-sheet detector protects automotive stamping lines

2025-10-30

-

Provincial Auto Industry Research Tour | Atonm Engages with the Automotive Supply Chain, Empowering Smart Manufacturing through Sensors

2025-10-11