Project Services

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website. Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link Cookie Policy.

Agree

Single Sensor

Image Sensor

2023-04-04

According to reports, Tesla is exploring construction of a new battery factory in the US and plans to cooperate with CATL. Insiders say Tesla intends to adopt a cooperation model similar to Ford and CATL. Last month Ford announced a $3.5 billion investment to build a lithium iron phosphate battery plant in Marshall, Michigan. The plant will be wholly owned by Ford while CATL will provide technology and service support for the plant.

Lithium batteries have become a key technology in the new energy sector, with multiple advantages and opportunities. The new energy industry, including electric vehicles, renewable energy and energy storage systems, is developing rapidly, and lithium batteries play a core role in this growth.

Growing demand for electric vehicles and renewable energy systems is creating major opportunities for the lithium battery industry. According to Allied Market Research, the global lithium-ion battery market is expected to reach USD 129.3 billion by 2027, with a CAGR of 18.0% from 2020 to 2027. This growth is driven by rising EV demand and increasing needs for renewable energy storage.

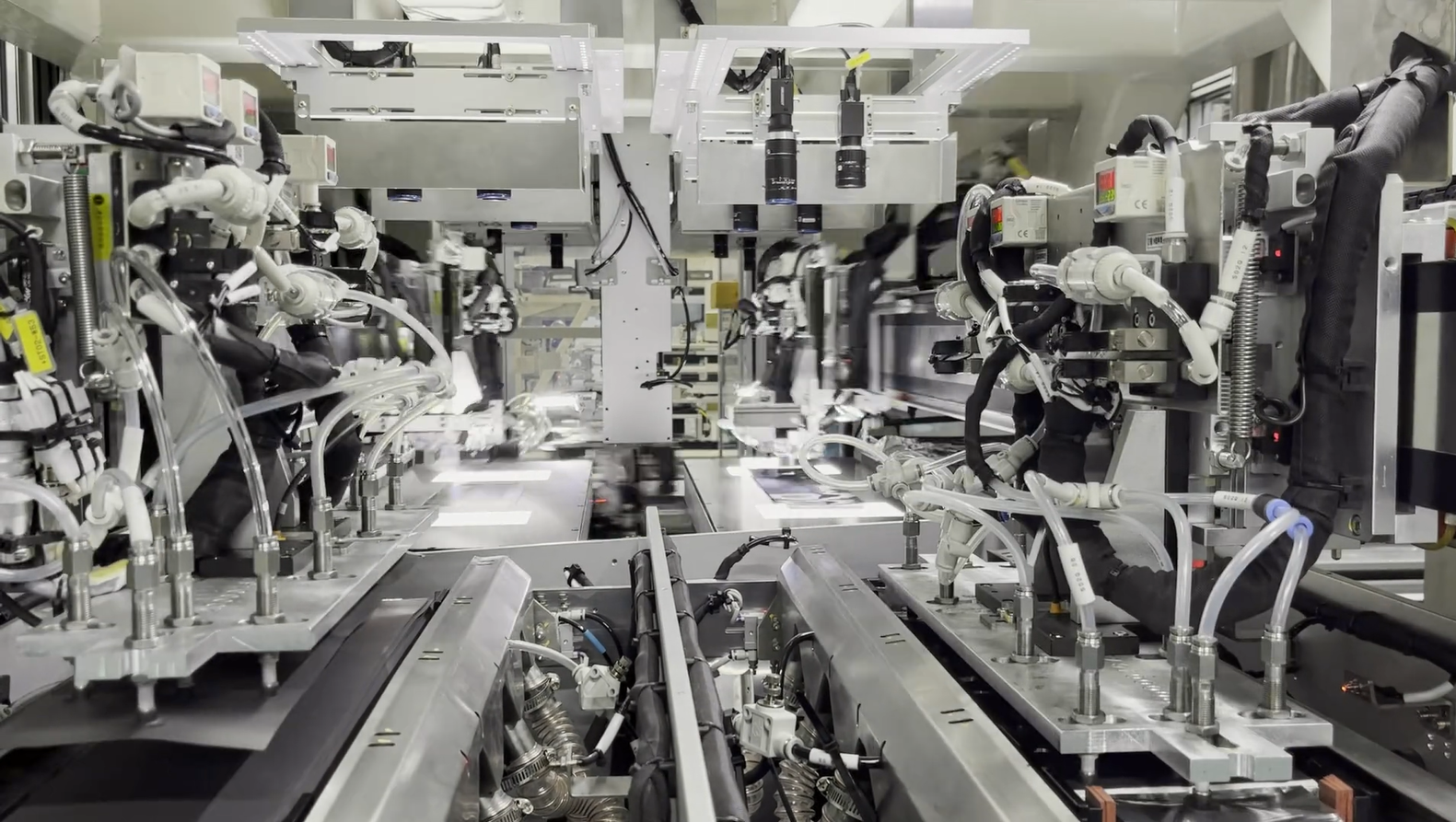

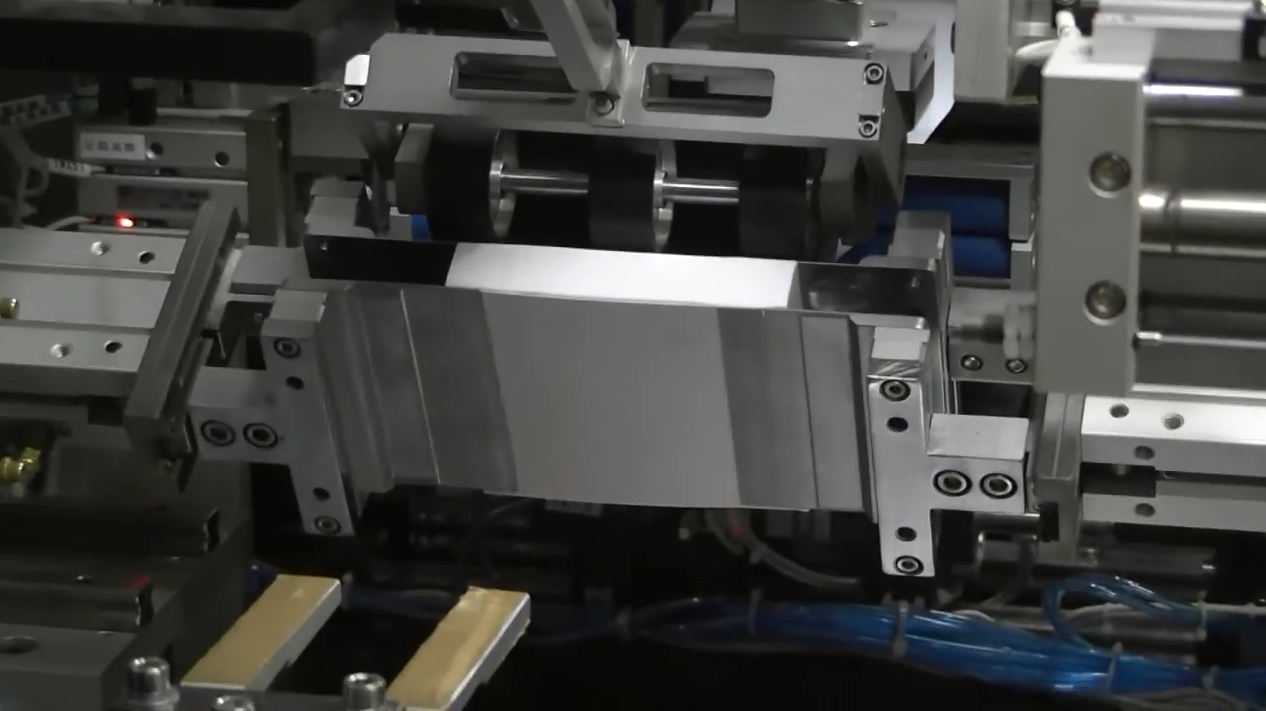

Different battery formats require different manufacturing processes; the two mainstream processes today are stacking and winding. Atonm believes that stackers and winders are core equipment in lithium battery production, and their accuracy directly affects product quality and safety. Sensors act as key aides on the production line, detecting tiny deviations to ensure high-quality, efficient production.

Sensor capabilities in key lithium battery processes

Typical scenario one: in the stacking process, a Metal Double-Sheet Detector ensures there is no double feeding or copper-aluminum mix during stacking.

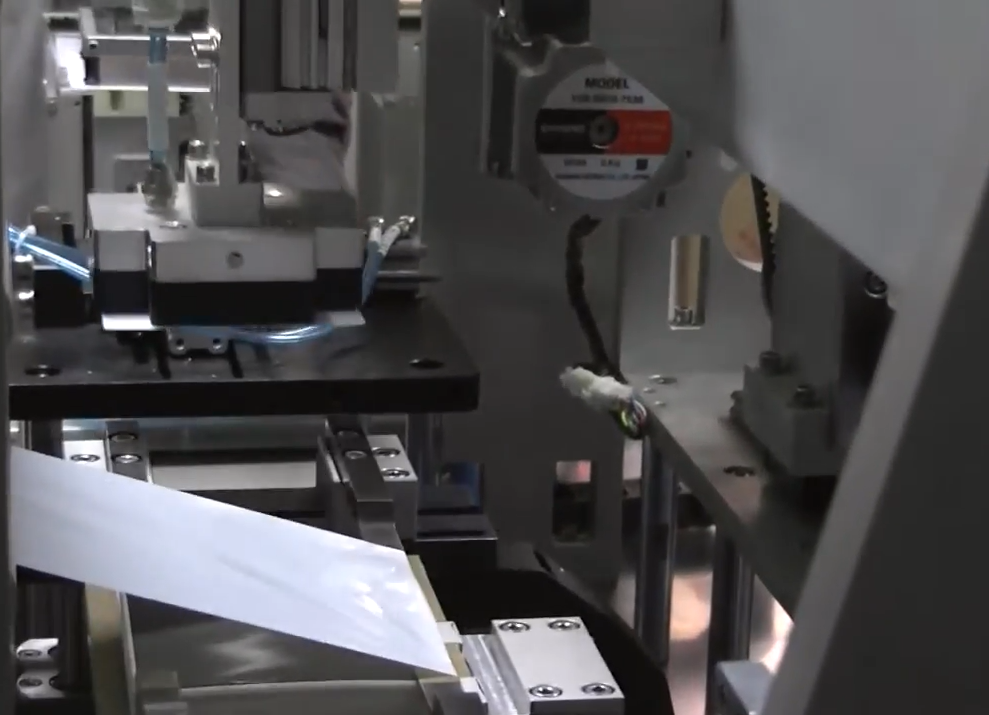

Typical scenario two: in stacking, edge-position sensors measure the separator edge to ensure correct alignment during Z-fold stacking.

Typical scenario three: in winding, the precision and measurement speed of alignment sensors during unwind and rewind directly affect winding quality and electrode damage detection accuracy.

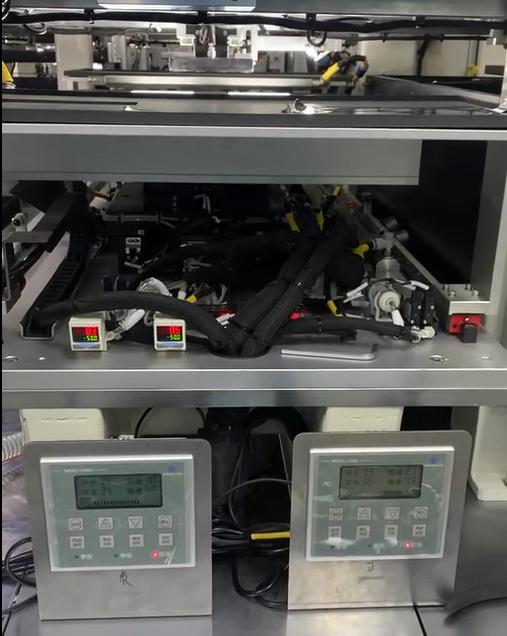

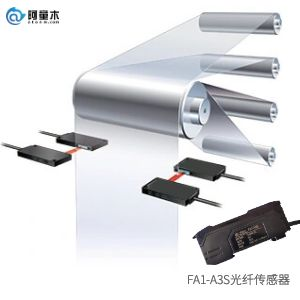

For diverse application scenarios, Atonm Sensors offers the Metal Double-Sheet Detector MDSC-1000L and the FA1-A3S fiber alignment sensor, delivering higher performance, faster measurement speed and versatile features to accelerate lithium battery production.

Atonm Sensors empowers precision manufacturing with domestically developed detection equipment, extending expertise from semiconductor precision manufacturing into the lithium battery field. By addressing pain points in electrode preparation, Atonm equips stackers and winders to improve manufacturing accuracy and speed.

MDSC-1000L Metal Double-Sheet Detector is a lithium-industry specific model for stack detection, designed for light, small and thin materials with custom M8 and M12 small probes for high reliability and the ability to distinguish copper-aluminum mixing.

FA1-A3S fiber alignment sensor is designed for high-speed winding in the lithium industry, featuring an industry-leading 50μs ultra-fast response and a compact body suitable for various mounting environments.

Metal Double-Sheet Detector

Preventing double feeding in stacking

In stacking, robotic feeders are commonly used. Negative pressure suction between sheets can easily cause double feeding. Some stacker designs may also mix copper and aluminum, which would result in scrapped products.

To address these issues, we recommend the Atonm MDSC-1000L Metal Double-Sheet Detector. The detector performs dual-sheet checks after the robot picks up a sheet to effectively prevent double feeding. It can detect sheet thicknesses from 0.01mm to 1mm, reach speeds up to 1200 pcs/min, and uses non-contact detection to avoid material damage and loss.

Alignment sensors enable

High precision and high yield in winding

Winding is a mainstream process with long development history, low cost and high efficiency and yield. As cylindrical cells scale up, winding improvements accelerate industrialization. However, winding can cause issues like edge chipping, burrs, electrode expansion and separator stretching, which may scrap entire cells. Equipment must ensure consistent material lines during unwind and rewind.

In this case, the Atonm FA1-A3S analog fiber alignment sensor offers a 50μs response time, enabling precise alignment even at high winding speeds. It quickly detects changes and adjusts to ensure alignment accuracy, which is crucial for fast winding operations to maintain product quality and production efficiency.

As the lithium battery industry evolves, upstream materials and equipment will undergo innovation, with stacking and winding seeing wider application. This raises higher requirements for double-sheet detectors and alignment sensors in terms of performance and stability. Atonm will continue to align with the lithium battery industry, focusing on production challenges and continually improving manufacturing efficiency and quality to offer better products and services.

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support