Project Services

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website. Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link Cookie Policy.

Agree

Single Sensor

Image Sensor

2023-02-22

1. Company Introduction

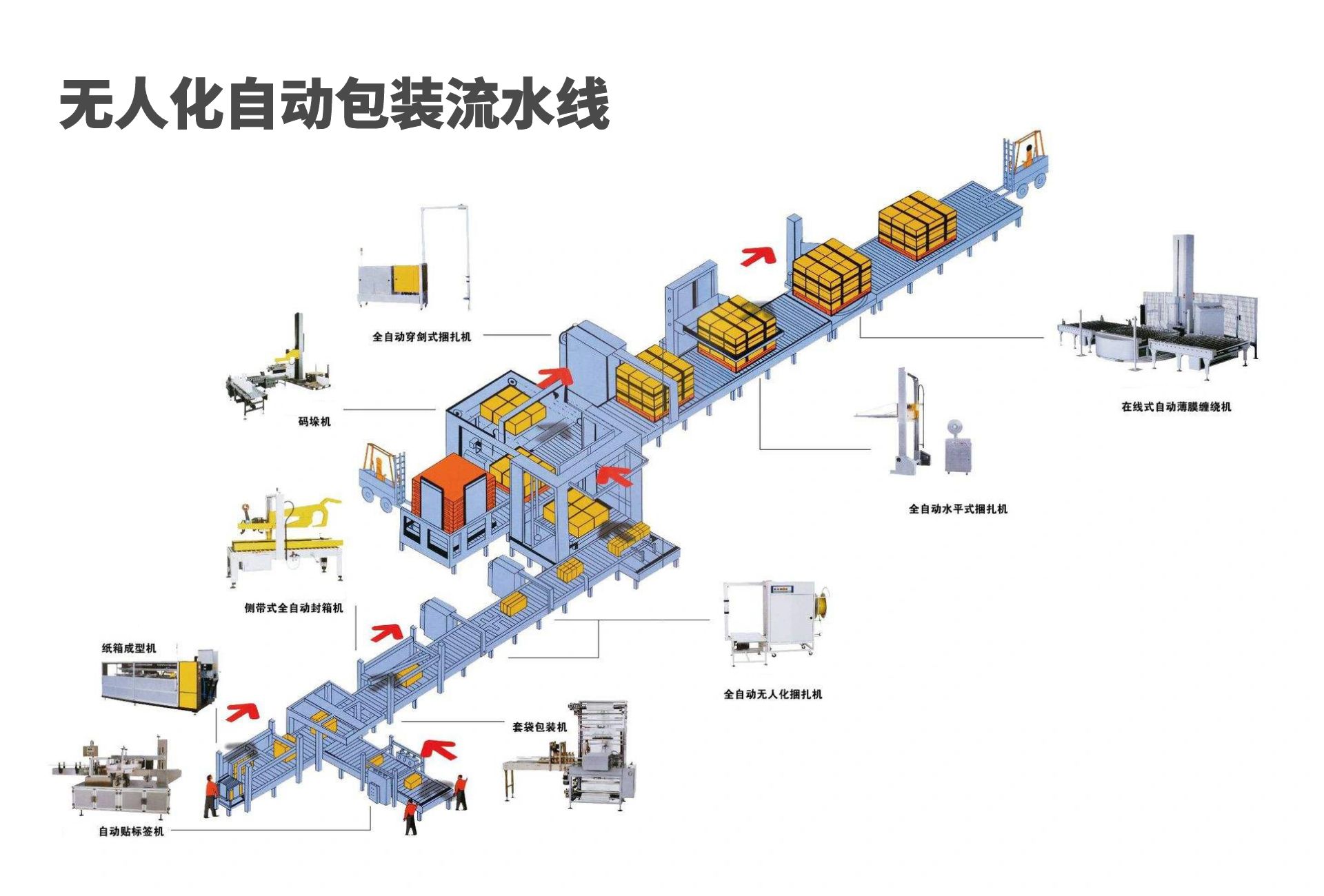

A Zhejiang food packaging company founded in 2004 specializes in food packaging production with advanced equipment and technology, providing high-quality, safe and environmentally friendly packaging solutions to the global food industry.

The company operates multiple fully automated food packaging lines handling various packaging materials such as plastic bags, cartons, tableware, bottles and cans.

2. Project Background

The company has a highly automated process from raw material input to packaging and inspection, using advanced management systems and sensors to monitor production parameters in real time for accuracy, consistency and traceability.

They contacted Atonm because previous color sensors produced misclassifications on packaging bags that affected production continuity.

3. Pain Points

1. Packaging materials on the line change frequently; different materials reflect light differently and affect sensor accuracy;

2. High surface gloss on some bags causes reflection that interferes with color sensing;

3. Some target colors are very similar and hard to distinguish;

4. Variable lighting conditions on the production floor also affect detection accuracy.

4. Solution

Atonm engineers tested packaging materials and recommended environmental lighting adjustments. We selected the Atonm CL2 color sensor which stores 8 colors and can recognize up to 4 colors simultaneously.

1. Excellent color matching accuracy and stable detection

The Atonm color sensor uses triple 16-bit RGB computation and can detect nearly 3,000 colors, accurately distinguishing subtle differences.

2. Adaptability to lighting and temperature changes

We tested materials under different lighting and temperature conditions and the CL2 maintained stable detection during continuous operation.

3. Anti-shake through algorithm and precision tuning

Algorithm and precision adjustments eliminate motion jitter, enabling stable detection at longer distances.

4. Adjust lighting on site

We recommend using non-flickering LED lights to provide stable illumination and improve detection accuracy.

5. Customer Benefits

1. Replacing with Atonm CL2 stabilizes production, reduces misclassification and downtime, and improves efficiency and product consistency;

2. Manual interventions are greatly reduced, saving labor costs.

Atonm is developing AI features to reduce light decay effects and continues to innovate to improve customer competitiveness.

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support