Project Services

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website. Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link Cookie Policy.

Agree

Single Sensor

Image Sensor

2021-12-07

Project Background

This project addresses robotic feeding overlap in home appliance body stamping. To protect expensive and complex molds, it is essential that robotic feeders supply single sheets during feeding.

Project Objective

Objective: Prevent robotic gripper from picking double sheets and damaging molds.

Solution

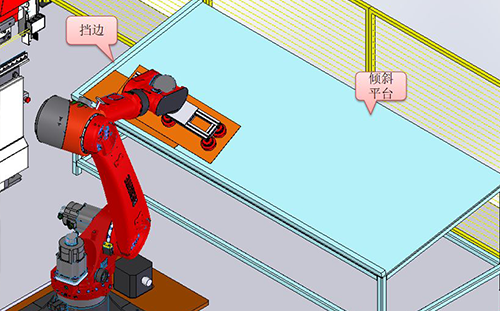

This solution equips the customer with Atonm Single-Sensor Metal Double-Sheet Detector MDSC-8000. When the robot arm places the sheet within the detector range, the detector is moved into position for detection to protect it from collisions during feeding. If a single-sheet signal is detected the robot proceeds; if a double-sheet signal is detected, the robot returns the sheet for re-pick.

Atonm Double-Sheet Detector MDSC-8000 is developed to prevent double-feed in robotic feeders for automotive and other industries, using a high-power single-sensor design to detect single or double sheets with one probe.

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support