2022-11-15

Magnetic Scale vs Optical Grating | Magnetic Scale Read Head: Position Measurement Solution

What is a Magnetic Scale Read Head?

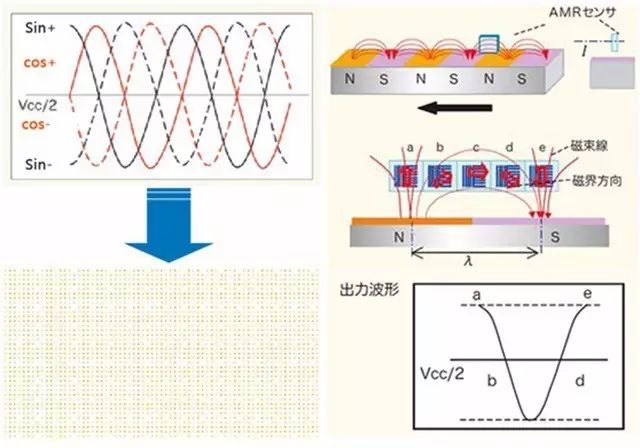

Composition: magnetic scale + read head

Definition: the read head reads evenly spaced magnetic waves recorded on the magnetic scale and maps them to lengths and positions.

The manufacturing method is similar to tape recording: the magnetic write head records strictly periodic magnetic waves on the scale. The distance between adjacent waves is called the grating wavelength or pitch.

Use cases: magnetic scales suit long-distance or transmission measurements with economy and efficiency, and they perform well in harsh environments like oil, chips and vibration.

Advantages and features of magnetic scale read heads

Advantage 1

Patented magnetic recording: 3-line N/S magnetic waves and vector detection eliminate ambiguity from traditional pulse-strength based edge detection.

Advantage 2

Compared with optical gratings, magnetic scale read heads are durable, wider in environmental tolerance and maintenance-free.

Advantage 3

Strong protection against harsh machining environments such as oil, cutting fluid and dust.

Advantage 4

Wide-ranging and high-end applications: magnetic scale read heads are used across industries including 3C electronics, glass, sheet metal machinery and metalworking. Typical equipment includes linear motors, semiconductors, LCD equipment, press brakes and CNC machines.

You May Be Interested

-

Atonm MDSC-9000T Dual-Channel, Single-Sensor Metal Double-Sheet Detector

2025-12-05

-

Non-Contact “One-to-Four” Double-Sheet Detector 1600S: A New Cost-Reduction and Efficiency Solution for Stamping Lines

2025-11-20

-

Mold damage, production delays? Atonm MDSC-8200T metal double-sheet detector protects automotive stamping lines

2025-10-30

-

Provincial Auto Industry Research Tour | Atonm Engages with the Automotive Supply Chain, Empowering Smart Manufacturing through Sensors

2025-10-11