2023-05-21

Color Sensor Applications in Industrial Equipment

Summary:

Color sensors are an important industrial technology widely used across many types of equipment. This article examines their applications in industrial equipment, including automated production lines, robotics, printing and packaging, showing how they improve production efficiency, optimize quality control, and enable intelligent manufacturing.

1. Color detection on automated production lines

Color sensors play an important role on automated production lines, providing real-time color checks to ensure product consistency and quality. For example, in automotive manufacturing, color sensors can verify body paint colors for automatic painting processes and compare them against standards to determine compliance. In the food industry, they support fast and accurate sorting by color.

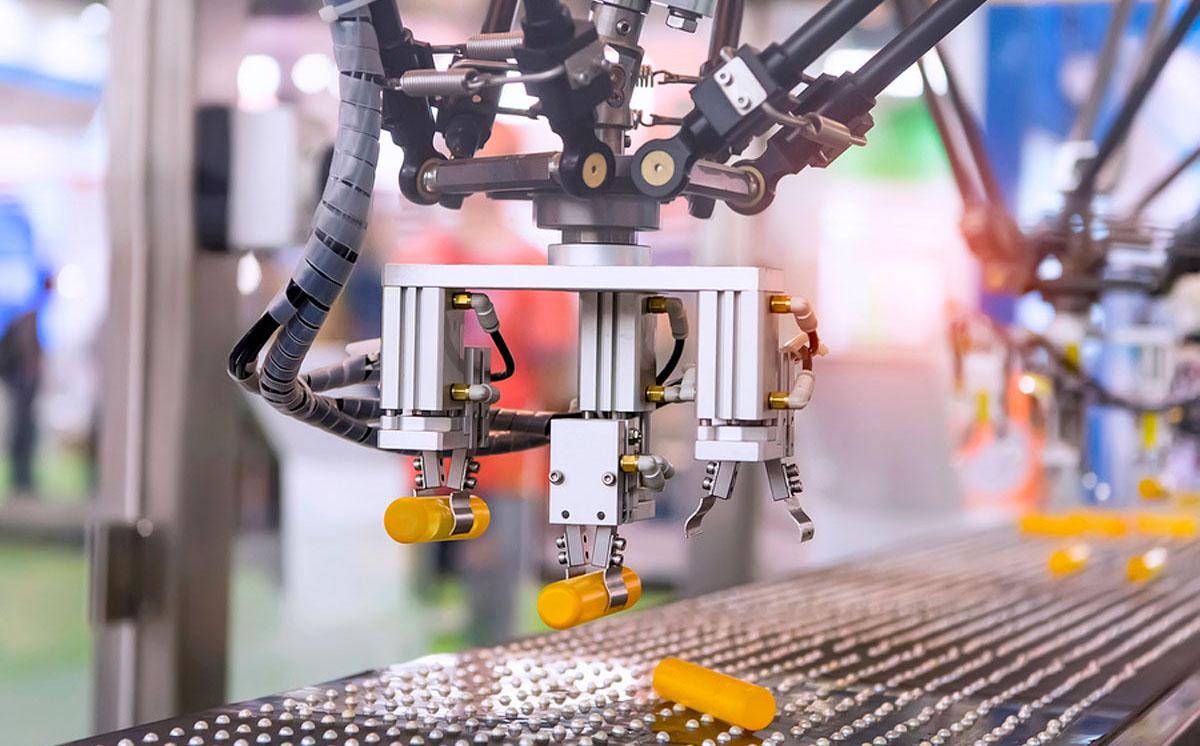

2. Machine vision in robotics

Color sensors are widely used in robotics for object recognition and task execution based on color features. Robots can identify and pick parts of different colors on assembly lines and handle material handling or packaging by recognizing container or label colors to ensure correct operations.

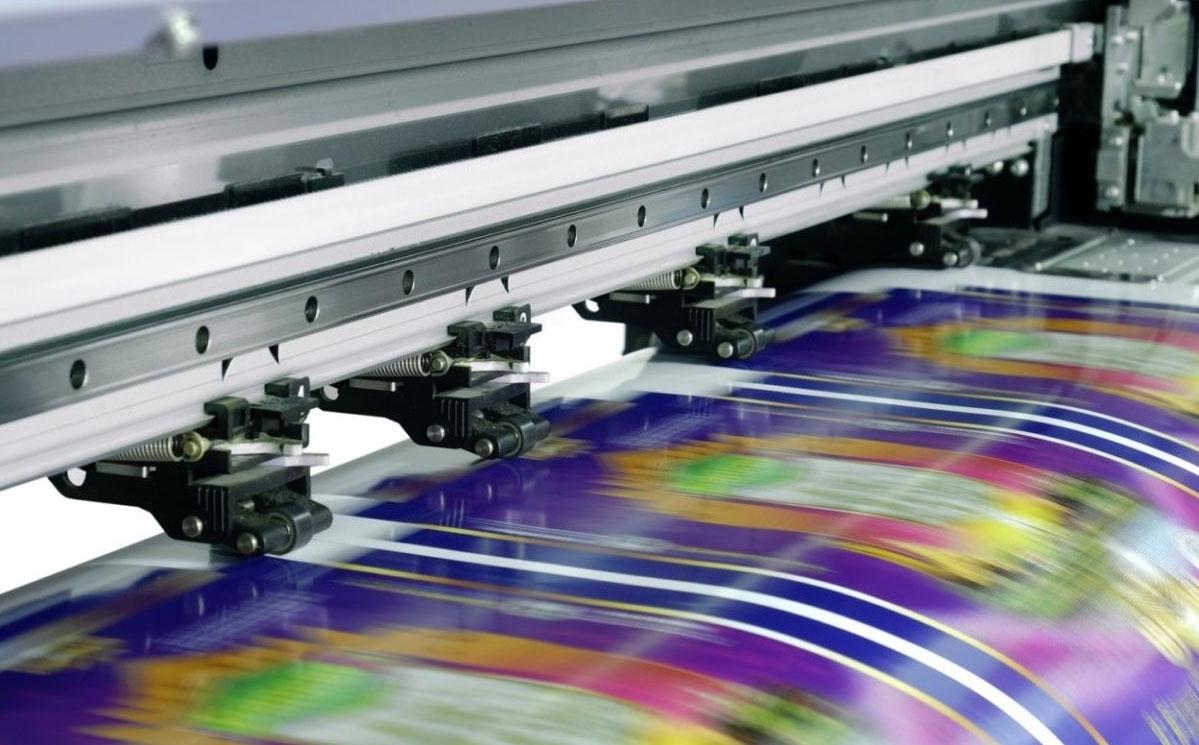

3. Quality control in printing and packaging

In printing and packaging, color sensors are primarily used for quality control, detecting color deviations in printed products and packaging materials by comparing them to preset color standards and enabling timely adjustments.

4. Color measurement for building materials and textiles

Color sensors are used in tiles and textile manufacturing to ensure batch-to-batch consistency and to detect color uniformity and deviations during production.

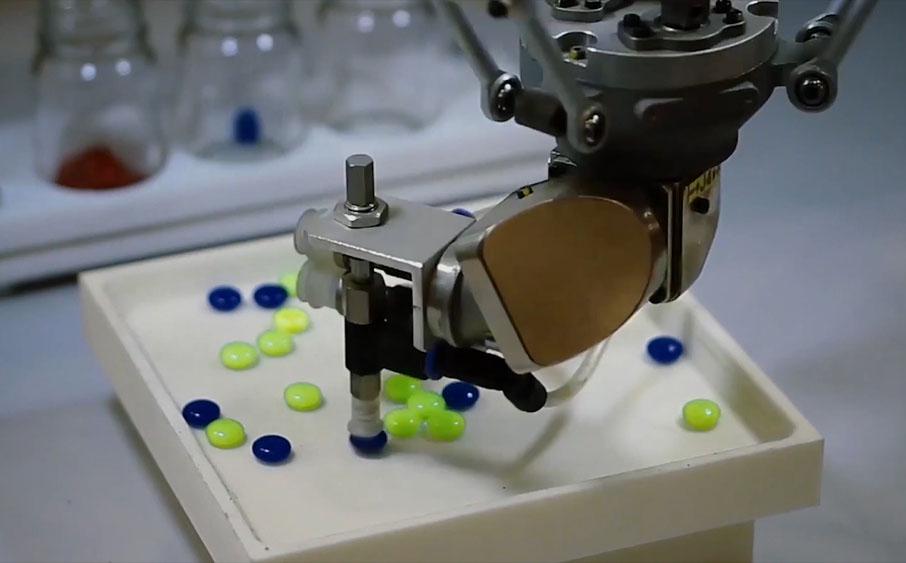

5. Color control in chemical and pharmaceutical production

In chemical and pharmaceutical processes, color changes may indicate product quality or composition changes. Color sensors enable real-time monitoring and comparison against defined color ranges to detect anomalies and adjust process conditions quickly.

Conclusion:

Color sensors have broad applications across automation, robotics, printing and packaging, building materials, textiles, chemical and pharmaceutical production. As high-precision, real-time devices they help improve efficiency and quality control. With ongoing technological progress and expanding use cases, their applications will continue to grow.

You May Be Interested

-

Atonm MDSC-9000T Dual-Channel, Single-Sensor Metal Double-Sheet Detector

2025-12-05

-

Non-Contact “One-to-Four” Double-Sheet Detector 1600S: A New Cost-Reduction and Efficiency Solution for Stamping Lines

2025-11-20

-

Mold damage, production delays? Atonm MDSC-8200T metal double-sheet detector protects automotive stamping lines

2025-10-30

-

Provincial Auto Industry Research Tour | Atonm Engages with the Automotive Supply Chain, Empowering Smart Manufacturing through Sensors

2025-10-11