Project Services

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website. Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link Cookie Policy.

Agree

Single Sensor

Image Sensor

2023-05-17

1. Company Introduction

The client is an automation equipment company in Dongguan founded in 2015, specializing in automated production equipment such as automotive part and motor assembly lines. The company focuses on innovation and product quality across every production step.

2. Project Requirements

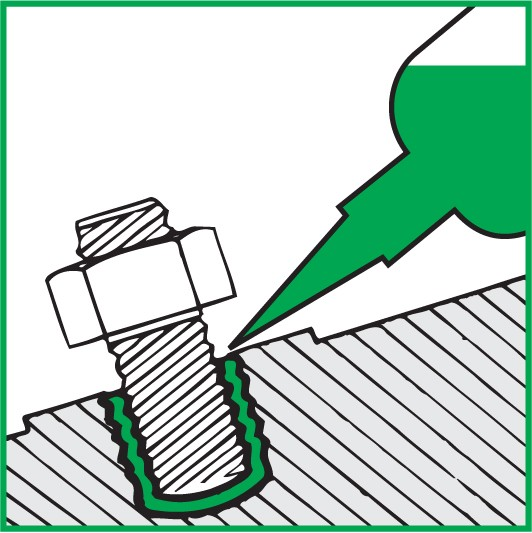

The production line requires automated inspection to ensure threadlocker adhesive coverage meets specifications. Different threadlocker colors indicate different strength levels. Missing or incorrect application may cause fastener loosening and affect safety, so an efficient, accurate inspection solution is required.

3. What is Threadlocker?

Threadlocker, also known as anaerobic adhesive, cures only when isolated from air. It commonly secures screws and prevents loosening over time by bonding to threads after curing. Different colors correspond to different strength levels, for example purple is lowest and red is highest.

4. Solution

When threadlocker is applied to parts, its color indicates coverage. Using the Atonm Color Sensor CL2, the system can identify different adhesive colors. The CL2 uses RGB light and a receiver with color filters to measure reflection intensity and compute color ratios. If measured color matches the predefined color, the sensor outputs a signal indicating correct application.

The CL2s 200μs detection speed allows use on high-speed lines. Parts are presented by robot arms to the adhesive area and checked by the color sensor; if coverage is incorrect, robot arms return the part for correction.

The CL2 supports multiple probe options to suit various sizes and detection distances, ensuring accurate measurement in tight spaces.

5. Customer Benefits

By using the Atonm Color Sensor CL2, the client automated threadlocker inspection to ensure correct adhesive application, improving production efficiency and reducing safety risks associated with loose fasteners.

6. Conclusion

This project uses the CL2 to verify threadlocker application accuracy and reliability, offering major benefits. The CL2s high precision, stability and ease of use make it suitable for complex color detection scenarios.

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support