Project Services

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website. Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link Cookie Policy.

Agree

Single Sensor

Image Sensor

2023-05-10

1. Company Introduction

The client is an equipment supplier based in Shenzhen with multiple branches nationwide. They focus on R&D, production, sales and service in industrial automation. Atonm engineers visited the clients Guangzhou Panyu production site to implement automated visual scanning for large automotive parts.

2. Project Requirements

The project requires automatic visual scanning of automotive parts to capture complete, accurate surface information. Since parts are usually large, single images cannot cover the whole surface, so precise displacement control is needed for accurate scanning.

This requirement demands:

1. High accuracy: Scanning data must be precise to avoid downstream errors.

2. Fast scanning speed: Large parts require efficient scanning without sacrificing accuracy.

3. Good stability: The system must remain stable to avoid interference and errors.

3. Solution

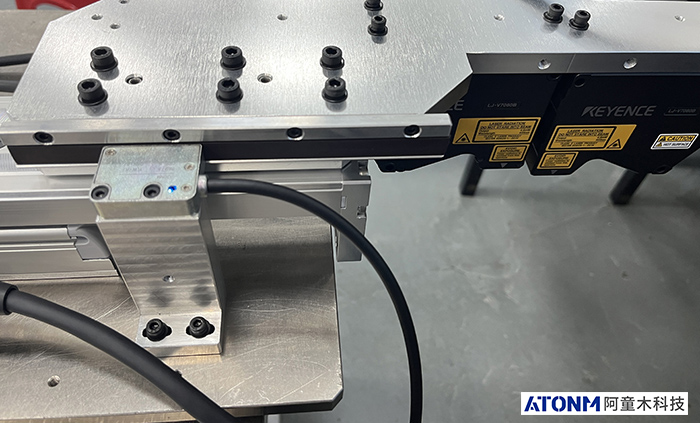

To meet the clients needs, the design uses a Keyence laser structured-light vision sensor for scanning and the Atonm Magnetic Scale Read Head to control precise scan positions via pulse-to-displacement. The Keyence vision sensor scans at 50μm intervals while the Atonm read heads stable and accurate output ensures scan precision and stability. This combination improves speed and accuracy while reducing operator error.

The Atonm Magnetic Scale Read Head MRR-H200 is a high-resolution, stable industrial read head suitable for motion control and automation. Key features include:

1. All-metal housing for water, dust and wear resistance;

2. Selectable resolution options: 1μm, 5μm, 10μm;

3. Tolerance to oil, liquids, dust and vibration.

4. Customer Benefits

After project completion, the client achieved:

1. Improved scanning accuracy: The Atonm read head reduced scan error and improved precision.

2. Increased scanning speed: Precise control enabled shorter scan times.

3. Enhanced system stability: Accurate control minimized interference and errors.

5. Conclusion

The solutions stability and accuracy were validated by on-site testing. Using the Atonm Magnetic Scale Read Head for pulse-to-displacement control ensures precise scanning and detection while improving efficiency and reducing maintenance. The read head is robust in harsh environments and helps guarantee stable operation.

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support