Project Services

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website. Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link Cookie Policy.

Agree

Single Sensor

Image Sensor

2022-11-30

Project Background:

With the development of electronic information technology, PCBs (printed circuit boards) are widely used in many electrical devices and are essential components. As the PCB industry grows quickly, machines such as laminators, board loaders and etching machines have replaced manual operations through mechanization and automation.

During PCB production, automatic feeding equipment often encounters double-sheet overlaps. If these overlapped sheets enter subsequent processes they can severely disrupt production order and threaten equipment safety, causing significant economic loss.

Project Challenges:

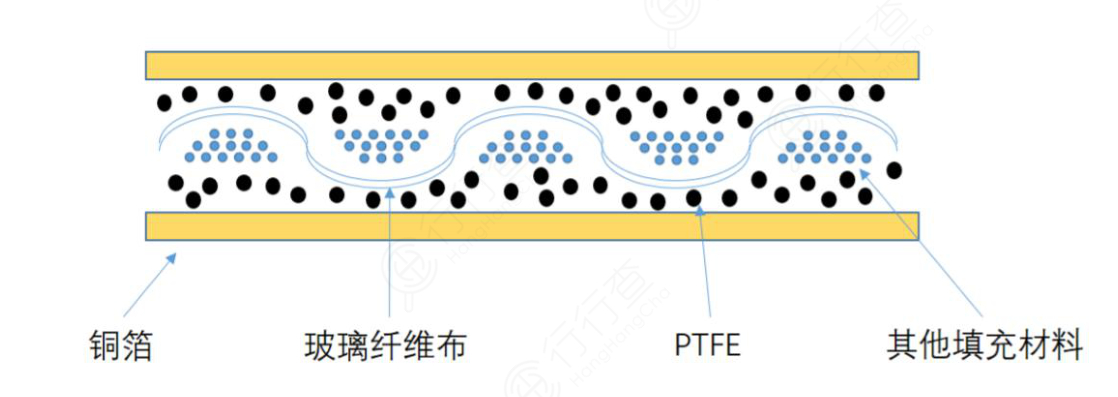

PCB laminating for foil feeding: the copper foil is extremely thin, requiring high detection accuracy from the metal double-sheet detector.

PCB etching for copper-clad laminate feeding: the epoxy plus copper sections are relatively thick, so the detector must handle larger thicknesses.

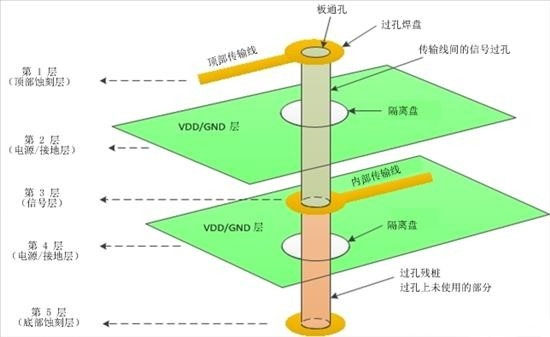

(PCB board structure)

PCB hole issue: PCBs contain many holes (component pins, locating holes, etc.) where ultrasonic waves can pass through, causing false readings.

Solution:

For PCB processing we selected the Atonm 1000B metal double-sheet detector main unit with a square detection probe. It can accurately detect single and double copper foils in laminating, detect metal portions through non-metal epoxy areas in etching, and is not affected by PCB pin holes, reliably identifying single vs double sheets.

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support