Project Services

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website. Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link Cookie Policy.

Agree

Single Sensor

Image Sensor

2025-04-17

(1) Company Overview

The customer is a company specializing in visual inspection solutions for chemical containers, boasting considerable technical expertise and a solid customer base in the industry. It has long been providing visual inspection solutions for various chemical manufacturers, committed to ensuring product quality and safety.

(2) Specific Inspection Requirements

The customer’s end clients are mainly engaged in the production of cosmetic bottles and impose extremely stringent quality requirements on cosmetic bottle caps. Among these requirements, the inspection of aluminum foil liners inside the caps is one of the critical processes. The customer explicitly requires that there must be no double or multi-layer aluminum foil liners inside the cosmetic bottle caps. Such defects would directly compromise the product's sealing performance. Cosmetic bottles with poor sealing may suffer from content leakage and deterioration, which would severely damage product quality and brand reputation.

(3) Limitations of Existing Inspection Methods

The customer’s existing visual inspection system can only detect the presence or absence of aluminum foil but cannot accurately distinguish between a single layer and double or even multi-layer liners. This limitation has become increasingly prominent as customers’ inspection requirements grow stricter, resulting in failure to meet client needs. There is an urgent need for a device capable of precisely detecting the number of aluminum foil liner layers.

(1) Solution Design

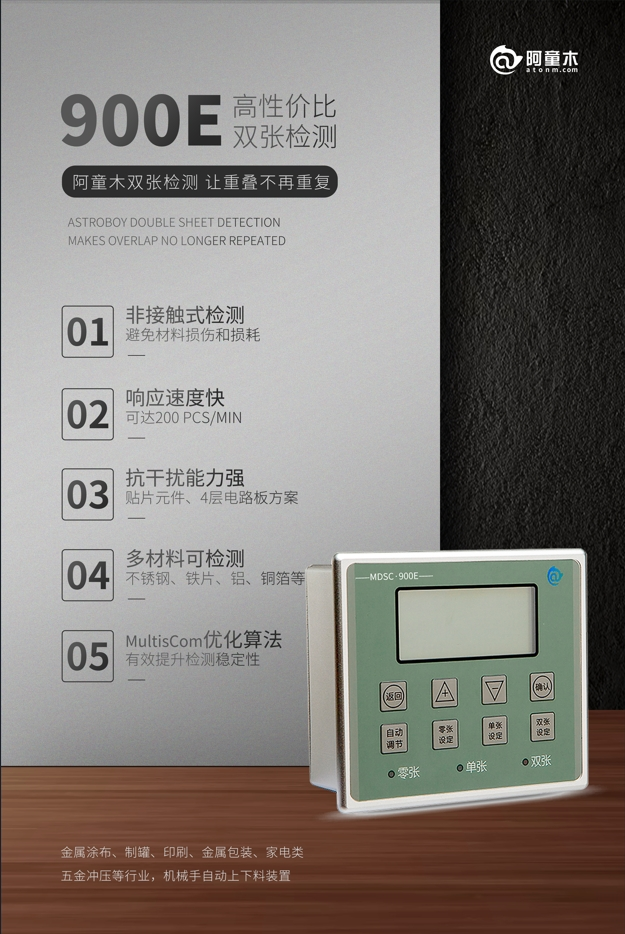

Based on the customer’s production process and inspection requirements, the technical team designed a detailed inspection scheme. The Atonm Metal Double Sheet Detector 900E is installed on the cosmetic bottle cap production line, positioned after the visual inspection equipment, to conduct a secondary inspection of the aluminum foil liners, ensuring detection accuracy and reliability.

The Atonm Metal Double Sheet Detector 900E is a high-precision device specially designed for metal sheet detection. It adopts advanced electromagnetic induction technology, enabling rapid and accurate detection of the number of thin metal sheet layers, and is suitable for double or multi-layer detection of various metal materials.

(2) Technical Advantages

High-Precision Detection

It can accurately distinguish between single-layer and multi-layer aluminum foil liners with a detection accuracy rate of over 99.9%, ensuring that no double or multi-layer defects are missed.

Strong Adaptability

It is suitable for detecting aluminum foil of different thicknesses and materials. Whether for standard or special specifications of aluminum foil liners inside cosmetic bottle caps, it can achieve effective detection.

Easy Installation

The sensor features flexible mounting methods and can be easily integrated into the existing production line without requiring large-scale modifications, thus saving installation time and costs.

Real-Time Monitoring

It enables real-time detection of single or double aluminum foil layers and provides timely feedback on inspection results. Once double or multi-layer issues are detected, it immediately triggers an alarm to facilitate prompt handling by operators.

(3) Inspection Principle

The Atonm Metal Double Sheet Detector 900E emits high-frequency electromagnetic signals. When the signals pass through the aluminum foil liners, induced eddy currents are generated. The device can accurately determine the number of aluminum foil layers based on changes in the eddy currents. When double or multi-layer aluminum foil is detected, the intensity and distribution of the eddy currents will undergo significant changes, upon which the device will send out an alarm signal.

(1) Significant Improvement in Inspection Performance

After the introduction of the Atonm Metal Double Sheet Detector 900E, the customer’s problem of being unable to distinguish the number of aluminum foil liner layers was successfully resolved. The device can accurately detect double or multi-layer aluminum foil, meeting the customer’s accuracy requirements. It effectively ensures the sealing performance of cosmetic bottle caps and improves product quality.

(2) Guaranteed Production Efficiency

The device’s real-time monitoring function allows operators to identify and address problems promptly, avoiding production line shutdowns and product rework caused by double or multi-layer aluminum foil issues. This has improved production efficiency and reduced production costs.

(3) Enhanced Customer Satisfaction

The customer is highly satisfied with the inspection results, recognizing that the solution has effectively resolved their quality challenges and enhanced the market competitiveness of their products. Meanwhile, the stable operation of the device and high-quality after-sales service have also earned the customer’s trust and praise.

In this case, the Atonm Metal Double Sheet Detector 900E, relying on its advanced technology and outstanding performance, has successfully solved the customer’s challenge in aluminum foil inspection for cosmetic bottle caps. The application of this device has not only improved product quality and production efficiency but also helped the customer gain an excellent market reputation. This case demonstrates that when facing complex inspection requirements, selecting the appropriate inspection equipment is the key to solving problems. With its high precision, strong adaptability, and user-friendliness, the Atonm Metal Double Sheet Detector 900E has become a reliable choice in the field of thin metal sheet detection.

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support