Project Services

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website. Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link Cookie Policy.

Agree

Single Sensor

Image Sensor

2023-04-29

This high-tech enterprise is located in Zhejiang and specializes in the research and development of mobile lithium battery stacking machines. They adhere to a philosophy of technological innovation and quality management, providing high-quality products and services. Currently, they are developing an efficient and stable stacking machine and are seeking an effective solution to the problem of metal sheet overlap in the tab feeding mechanism.

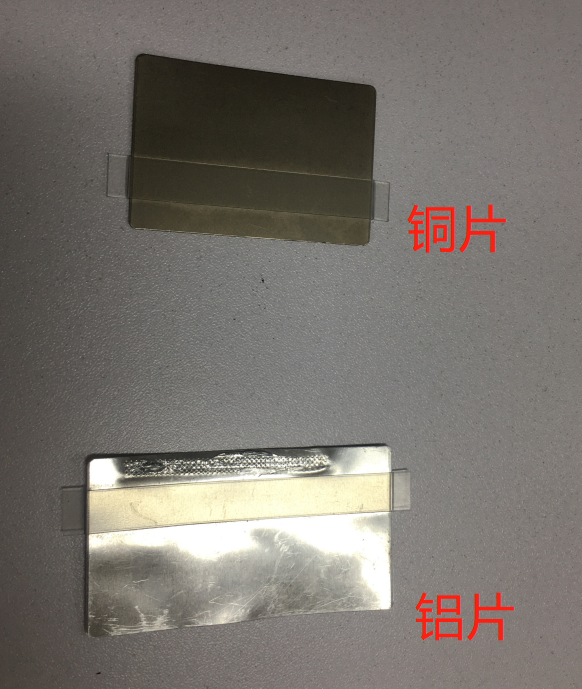

In the mobile lithium battery stacking machine, the tab feeding mechanism is a critical component responsible for delivering metal sheets such as copper and aluminum from storage to the stacking area. During this process, it is essential to prevent metal sheet overlaps and copper-on-aluminum overlaps, as these defects can lead to battery scrap.

To address this issue, the company requires a device capable of distinguishing single and double sheets of the same metal material within the tab feeder. The device must also detect copper-on-aluminum overlaps to prevent battery failure caused by tab stacking.

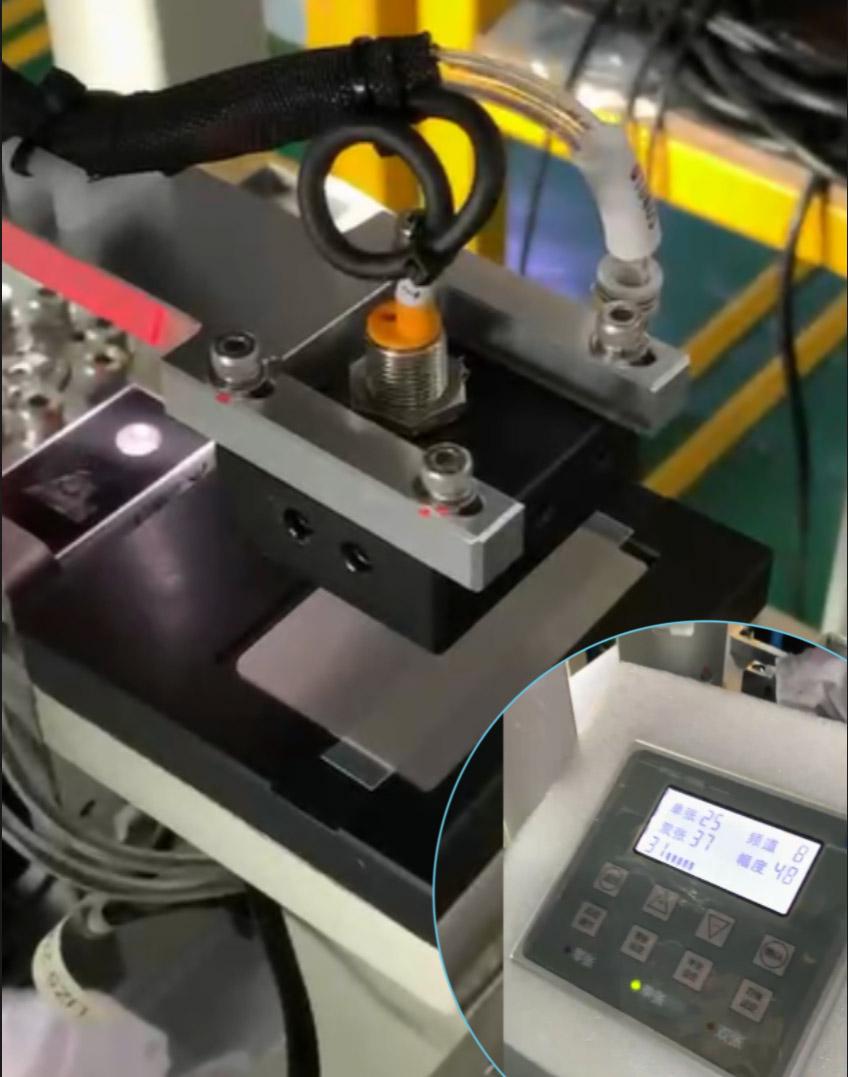

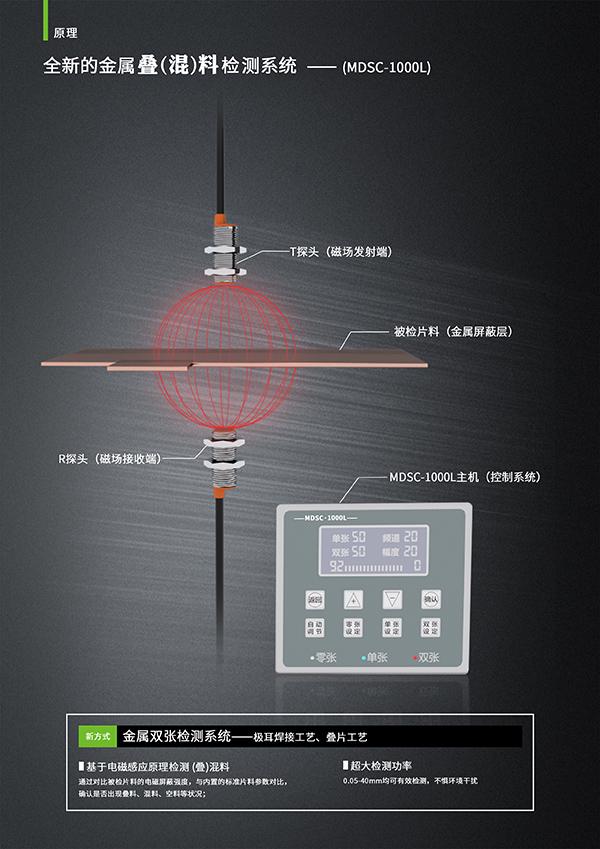

To meet the companys requirements, they selected the Atonm Metal Double-Sheet Detector 1000L, which is well suited for this scenario. This detector can identify single and double sheets of the same metal and can also detect copper-on-aluminum overlaps.

Installed at a specific position in the tab feeder, the detector accurately monitors the sheet condition. When a sheet passes through, it automatically identifies the material type and sheet count and reports this data to the machine control system.

By using the Atonm Metal Double-Sheet Detector 1000L, overlaps and copper-on-aluminum stacking in the tab feeder are avoided, effectively reducing battery scrap rates and improving product quality and production efficiency.

The company resolved the metal sheet overlap issue in the tab feeder using the Atonm Metal Double-Sheet Detector 1000L, lowering battery scrap rates and improving quality and efficiency. The detector also identifies copper-on-aluminum overlaps, further enhancing product reliability.

The Atonm Metal Double-Sheet Detector 1000L is an excellent solution that accurately identifies single and double sheets and detects copper-on-aluminum overlaps, preventing battery scrap caused by tab stacking.

The companys adoption of the Atonm Metal Double-Sheet Detector 1000L was successful: they solved overlap issues in the tab feeder, improved product quality and production efficiency, and the solution is also applicable to other industries such as electronics and automotive parts.

Choosing the right equipment and solution is vital to improve product quality and productivity. Companies should select the most suitable equipment based on actual needs to achieve business success.

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support