Project Services

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website. Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link Cookie Policy.

Agree

Single Sensor

Image Sensor

2023-03-24

1. Overview

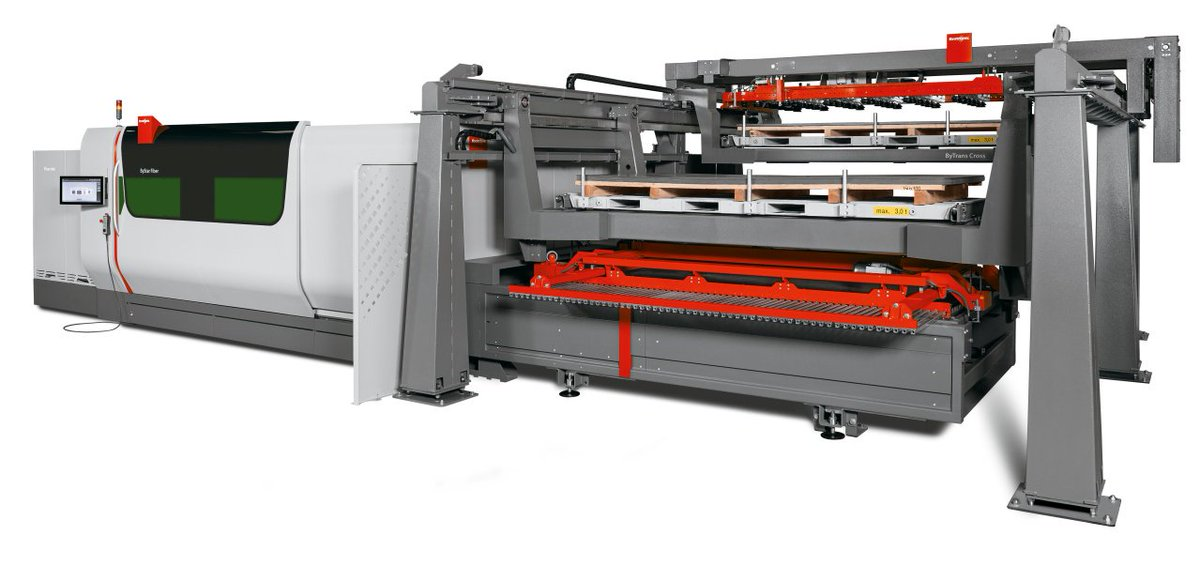

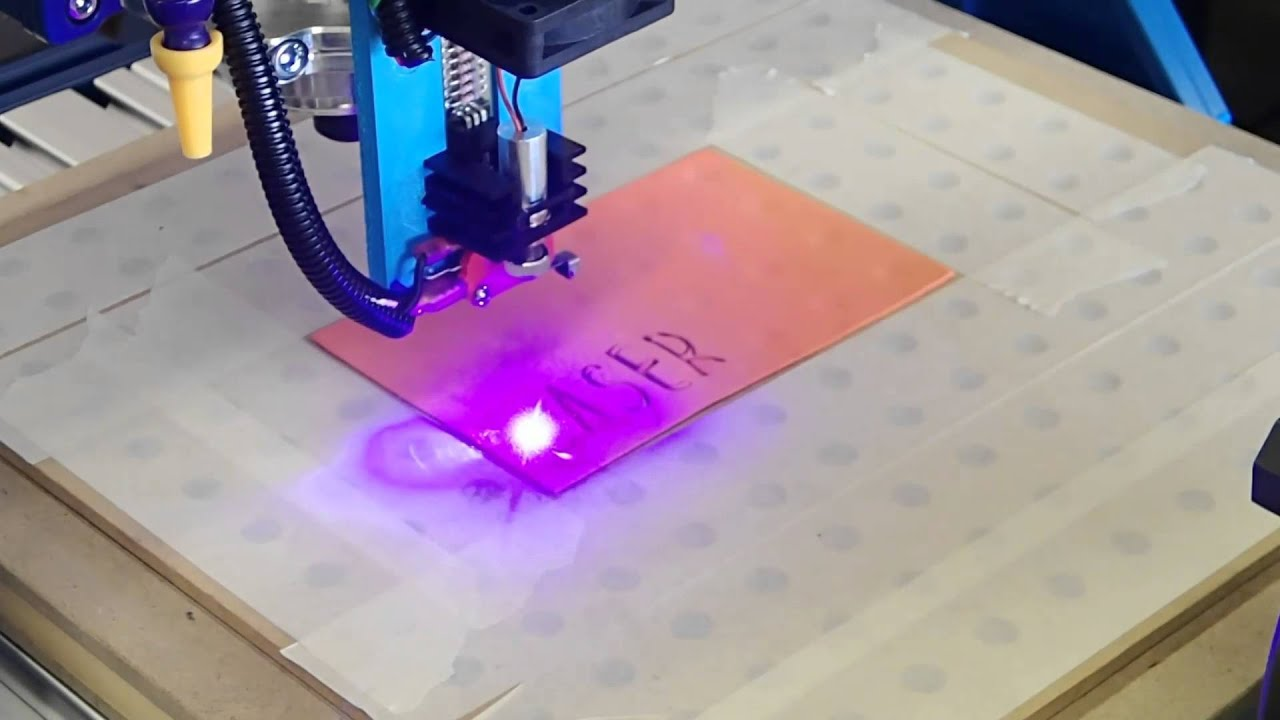

The Atonm magnetic scale read head is a high-precision measurement device suitable for integration into laser cutting motion control systems to provide accurate monitoring and control during cutting. This solution is designed to improve laser cutter precision and stability while reducing operating costs and improving throughput.

2. Details

Atonm read heads’ stability and anti-interference performance are key for laser cutting:

1. Choose the appropriate read head: Laser cutters require high resolution, speed and interference resistance; select a read head that meets these criteria.

2. Install the read head precisely on the motion axis; correct spacing prevents vibration and interference.

3. Commissioning and calibration: Use professional tools and software to fine-tune accuracy and stability.

4. Software integration: Integrate the read head into the cutter’s control software to read and convert signals into motion commands.

3. Advantages

1. Improves precision and stability, reducing cut errors and improving quality.

2. Protective design reduces dust and metal debris interference, extending service life.

3. Digital signal transmission increases stability and reduces noise.

4. Optimized interfaces and circuitry improve interference resistance.

5. Integrated control enables precise monitoring and control, raising productivity and lowering tool wear and costs.

4. Conclusion

This read head solution helps laser cutters improve precision and stability, reduce cutting errors, and lower costs — delivering important benefits in metal processing and other cutting-intensive industries.

Solution Design

Application Validation Support

Parameter Optimization Guidance

Commissioning Support